文章

解决实际问题的15个固态继电器故障排除技巧

正在为固态继电器问题而苦苦挣扎? 这 15 个技巧可帮助您快速发现故障、解决实际问题并恢复可靠的性能。

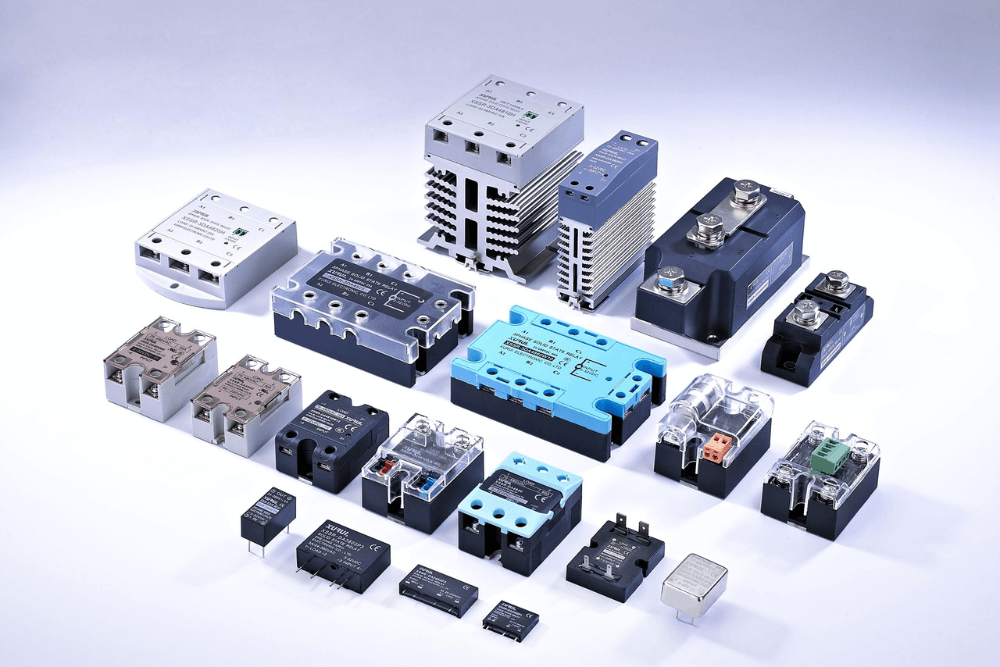

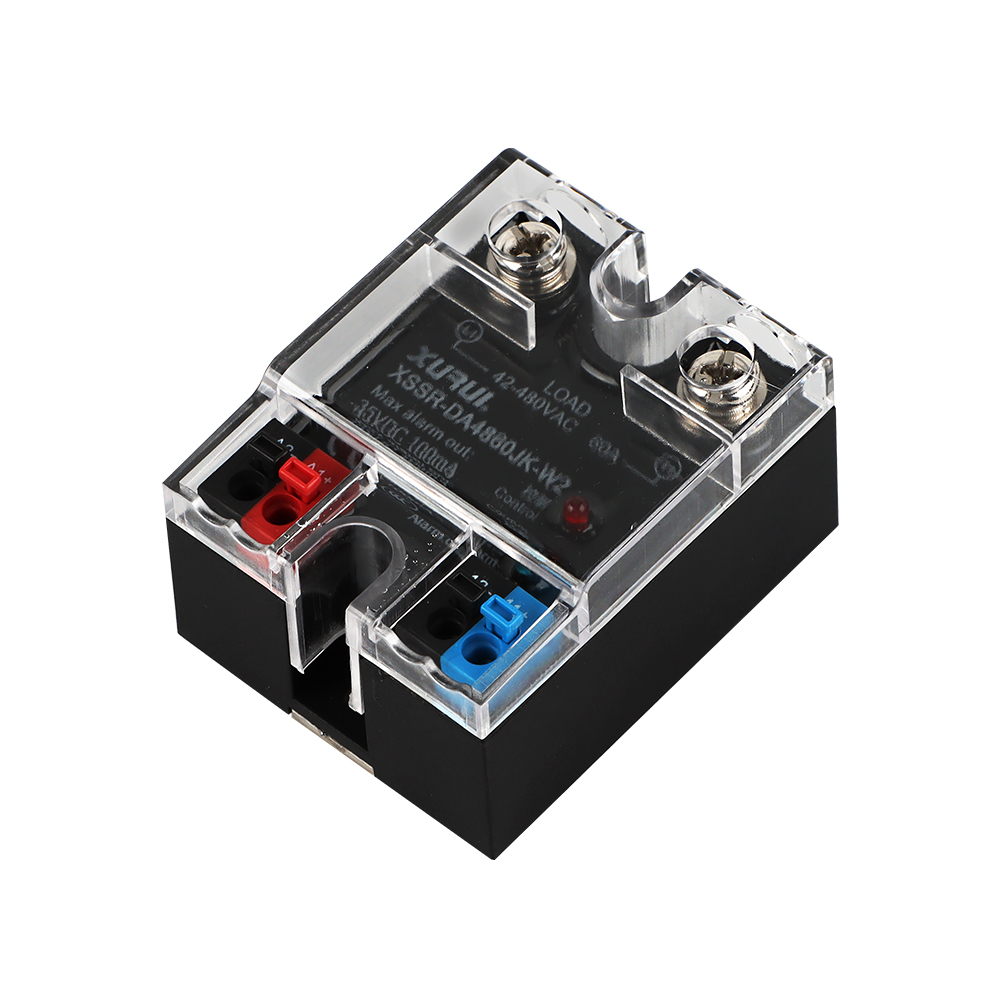

什么是固态继电器 (SSR)?

SSR的基本工作原理

固态继电器 (SSR) 是一种无需移动部件即可控制电源的电子开关。 它使用半导体(如双向可控硅开关、晶闸管或 MOSFET)在控制电压触发时打开或关闭电路。 SSR 响应来自 PLC 或微控制器的小输入信号,以切换更大的交流或直流负载,提供安静、快速和无磨损的运行。

SSR 和机械继电器之间的主要区别

与机械继电器不同,SSR 不会发出咔嗒声或弧度。 其固态设计使其成为需要静音或快速切换的环境的理想选择。 由于物理接触点,机械继电器可能会磨损得更快,而 SSR 的使用寿命更长,但需要热管理。

固态继电器在现实世界中的使用情况

SSR 在 3D 打印机、HVAC 系统、工业烤箱、照明控制、实验室仪器和智能家居中很常见。 业余爱好者经常将 SSR 与 Arduino 或 Raspberry Pi 一起使用,通过 GPIO 引脚安全地控制高压负载。

使用 SSR 的利弊

SSR 耐用、静音且可靠。 它们切换速度快,在恶劣环境中也能很好地工作。 缺点包括发热、成本和关闭时的漏电流。 使用散热器和适当的负载匹配以最大程度地减少问题。

为什么固态继电器会发生故障或故障?

SSR 在日常使用中失败的 5 大原因

- 由于缺少散热器或气流不畅而导致过热。

- 来自小型继电器的过流。

- 接线错误,尤其是 AC/DC 不匹配。

- 没有浪涌保护的电压尖峰。

- 控制信号弱,无法触发激活。

关于 SSR 的常见神话和误解

SSR 不会永远持续下去; 高温和误用会缩短使用寿命。 关闭时漏电流正常。 并非所有 SSR 都是通用的; 始终匹配负载类型和控制信号。

损害 SSR 寿命的环境和安装因素

热量、灰尘和通风不良会降低 SSR 的性能。 使用散热器和导热膏正确安装。 避免在没有保护措施的情况下潮湿或肮脏的环境。

固态继电器应该持续多长时间,以及缩短时间的原因

如果安装得当,SSR 可以使用 5-10 年。 经常出现故障是由于以最大额定值运行、跳过冷却步骤或未能防止浪涌电流。

常见的 SSR 问题及其原因

SSR 未打开(负载未激活)

检查是否存在控制电压tage (3–32V DC)。确保接线极性正确且负载连接正确。

SSR 未关闭(始终卡在开启状态)

可能是由于热量或浪涌导致的输出短路。尝试移除输入信号并进行测试。如果使用感性负载,则添加缓冲器。

负载闪烁或行为不稳定

当控制信号较弱或有噪声时发生。使用稳定的电压源,并考虑光耦合器或电阻器以实现更清洁的触发。

SSR 变热或融化

表示散热不良。安装带有导热膏的散热器,避免安装得太靠近热源。

SSR 在没有输入信号的情况下意外激活

电压尖峰或 EMI 可能会错误地触发 SSR。使用屏蔽电缆、接地和 RC 滤波器来稳定输入。

SSR 在测试中工作,但在实际系统中失败

SSR 的额定值可能不正确或对环境噪声敏感。在实际负载下进行测试,并确保正确的 SSR 类型(AC/DC、零交叉/随机点火)。

分步固态继电器故障排除指南

安全第一:开始测试前要做什么

在接触 SSR 端子之前,请务必关闭电路并放电电路。使用绝缘工具并戴上手套。

如何检查控制输入侧

使用万用表检查预期的输入电压范围。确保您的控制器提供强大而干净的信号。

如何测试负载和输出侧

在控制激活的情况下,检查负载侧是否接收到全电压。否则,SSR 可能开路或负载接线可能有故障。

常见万用表读数及其含义

- 输入侧:3–32V DC = 良好的触发信号。

- 输出侧:部分泄漏正常;全电压关闭时表示可能出现故障。

如果一切看起来都很好,但仍然不起作用怎么办?

模拟实际负载并重新测试。缩短电线布线,测试接地,并考虑将 SSR 更换为更高额定值的 SSR。

如何在 SSR 问题开始之前预防它们

根据负载类型(电阻、电感等)选择合适的 SSR

匹配要加载的 SSR 类型。对电阻负载使用过零点,对感性负载使用随机点火。始终检查数据表。

为什么降额是长期可靠性的必要条件

不要满负荷运行 SSR。降额 30-50%,以防止热量、浪涌或电流尖峰。

以正确的方式使用散热器、缓冲电路和浪涌保护

散热器和导热膏有助于控制热量。缓冲器抑制反电动势。MOV 可防止交流尖峰。

SSR 布线、安装和间距的最佳实践

安装在单元之间有空间的金属表面上。保持输入线和输出线分开。正确拧紧所有端子。

长期运行系统的定期检查技巧

在关键任务系统中,每 5-7 年检查一次端子、清洁灰尘、监控热量水平并更换 SSR。

真实案例:其他人如何解决他们的 SSR 问题

案例 1:3D 打印机电源模块中的 SSR 故障

一位制造商升级了他的 3D 打印机,将 SSR 用于加热床。起初它有效,但几周后,床停止加热。

为什么失败:他使用了没有散热器的 SSR。连续电流消耗使 SSR 过热并烧毁输出级。

他是如何修复的:他更换了 SSR,添加了一个合适的铝制散热器和导热膏,并将其与其他组件隔开。从那以后一直很稳定。

案例 2:SSR 在面包店的工业烤箱中烧坏

一家面包店的工业烤箱在运行过程中突然停止加热。技术人员在控制面板内发现了一个烧焦的 SSR。

为什么失败:烤箱使用大电流电阻负载,但 SSR 的尺寸太接近负载的峰值电流。没有应用降额。

他们是如何修复的:他们用额定值高于负载 50% 的 SSR 替换了 SSR,并添加了一个风扇冷却散热器。他们还安排了季度检查,以防止将来出现故障。

案例 3:业余爱好者将 SSR 与 Arduino 一起使用,但不起作用

一位业余爱好者将 5V SSR 连接到他的 Arduino 来控制一盏灯。

但无论如何,灯从未打开过——尽管代码和接线看起来不错。

为什么失败:SSR 至少需要 5V 输入,但 Arduino 的数字引脚在负载下仅提供约 4.7V 电压,不足以触发继电器。

他是如何修复的:他在 Arduino 和 SSR 之间添加了一个简单的晶体管开关来放大信号。问题解决了——灯按照命令完美工作。

结论

固态继电器很可靠,但与任何组件一样,如果使用不当,它们可能会发生故障。通过了解它们的工作原理并遵循这 15 个故障排除提示,您可以快速找到并解决大多数问题。无论您是业余爱好者还是专业人士,一点知识对于保持系统安全、稳定和平稳运行大有帮助。