摇杆开关和拨动开关之间的区别

拨动开关和翘板开关是控制电气系统的两种最常见的类型。 选择合适的产品对于安全性、可靠性和易用性非常重要,无论是在汽车、工业、人工智能还是消费电子产品中。 本指南解释了它们在设计、作、安装和理想应用方面的差异,以帮助您选择正确的交换机并提高项目的安全性和性能。

对翘板开关和拨动开关的基础见解

翘板开关和拨动开关的主要工作是控制电路中的电流。 但根据用途,它们的形式、结构和用途大不相同。

了解翘板开关的工作原理及其使用地点

翘板开关的工作原理是在枢轴点上来回移动。 要停止电路,请按下开关的一侧并松开另一侧以将其打开。 开关表面保持平整光滑,易于按压。 翘板开关经常安装在电源板、家庭小部件和汽车面板中。 其纤细的形状和缎面设计使其非常适合注重外观和空间的用途。

了解拨动开关的工作原理及其使用地点

使用拨动开关打开或停止电路,拨动开关有一个上下或左右移动的杆或手柄。 许多用户发现开关设备给他们一个物理和响亮的“咔哒”响应,这让他们感到欣慰。 许多工业控制面板、重型机械和海军环境都使用拨动开关,因为它们坚固耐用且易于使用,即使戴着手套或在恶劣的环境中也是如此。

直接比较:翘板与拨动开关

头对头比较是了解哪种开关最适合您的唯一方法。 这部分列出了速度、风格和实用性方面最重要的变化。

作风格和用户交互

摇杆按钮和拨动按钮的工作方式确实不同。 翘板开关只需在平面上平稳按下即可。 这使得它们使用起来很舒适,并允许您打开和关闭效果而不会感到疲倦。 另一方面,拨动开关是翻转手柄的部件,它使开/关状态清晰,并通过物理反馈确认。 因此,拨动开关在了解开关正确状态很重要的故事中效果更好。

安装形状和空间要求

大多数翘板开关具有块状或圆形安装形状,使其与面板齐平并占用更少的水平空间。 拨动开关需要安装一个圆形或三角形孔,并且它们从面板表面伸出,因此需要更多的空间。 但是,摇杆开关可能会更好,但如果您需要能够流畅地看到和感觉到它们,如果面板上没有足够的空间,拨动开关会更好。

耐用性和耐环境性

在翘板开关和拨动开关之间进行选择时要考虑的一件重要事情是它们的使用寿命。 对于工业级拨动开关,外壳和内部组件通常更坚固,可以承受大量使用、灰尘、湿气和压力。 许多拨动开关具有防漏或密封性能,可在恶劣条件下使用。 事实上,尽管翘板开关在家庭环境中很坚固,但它们并不总是像拨动开关那样坚固或防漏。

成本、美观和保护考虑因素

在成本方面,翘板开关往往更便宜,因为它们更容易制造并且用于许多消费品。 它们看起来很时尚并且易于清洁,但如果损坏,可能更难自行修复或更换。 拨动开关有时更珍贵,但它们更容易维护,因为机械因素通常很容易接近和形成。 它们的经典风格赋予它们坚固的工业外观,非常适合工业环境。

每种交换机类型效果最佳的地方

根据接触、用途和房间,不同的地方需要不同种类的开关。 让我们看一些现实生活中的例子,说明摇杆和拨动开关何时效果最好。

汽车、船舶和工业环境

拨动开关是工业、海军和车辆环境中最常见的开关类型,因为它们在恶劣情况下工作良好。 因为它们坚固、具有良好的物理反馈,并且可以带有环境密封件,因此非常适合搬运发动机、泵、灯和重型机械。

消费电器和 DIY 电子产品

翘板开关通常更适合家用电子产品和市场电子产品。 它们体积小,易于放入家用电子产品、电动工具和其他日常用品中。 人们欣赏其扁平化的设计和易用性。 不过,对于需要坚固性和准确反馈的艺术家和专业人士来说,拨动开关可能仍然更适合独特的项目。

安装和接线注意事项

接线和放置是选择开关时很重要但经常被遗忘的部分。如果您知道什么最适合您的设置,则保证兼容性和安全性。

接线端子和连接器兼容性

螺纹端或焊片通常出现在拨动开关上。这些使得牢固连接电线成为可能。其中许多还具有快速断开连接,使安装速度更快。翘板开关上的刀片连接通常用于快速驱动连接。在翘板开关和拨动开关之间做出选择时,您应该考虑如何接线以及是否需要固定连接或快速访问表格。

改造:一个可以取代另一个吗?

从翘板开关转移到拨动开关并不总是那么容易。 由于它们的固定孔形状和尺寸不同,因此经常需要更换面板或使用转接板在它们之间切换。 可能还需要不同类型的线路分站,这可能意味着更改或获得新的连接。 在尝试从拨动开关转移到翘板开关或相反之前,您应该始终查看专门的规格和兼容性属性。

合规和安全标准

在市场和企业环境中,遵守安全规则和产品标准都很重要。 开关必须符合国际标准,以确保其安全、使用寿命长且工作良好。

监管标签和认证

在某些地方,翘板开关和拨动开关必须同时满足 UL、CE 或 RoHS 等电气安全标准。 对于工业或海军用途,拨动开关通常有额外的证书,表明它们可以处理水、防锈和承受压力。 寻找这些批准非常重要,尤其是在将开关放入需要安全的系统中时。

基于应用的安全指南

不同的情况需要不同的安全规则。 例如,公共汽车和船只中使用的开关必须适合处理运动和水,而家庭中的开关必须防止人们受到电击或引发火灾。 根据作,您可能需要选择防漏拨动开关或具有防潮外壳的翘板开关。

供应商的采购建议

仅仅比较价格以获得时尚的交易是不够的。 与安全交换机提供商合作可以帮助您确保质量、合规性和长期性能。

购买前如何估算规格

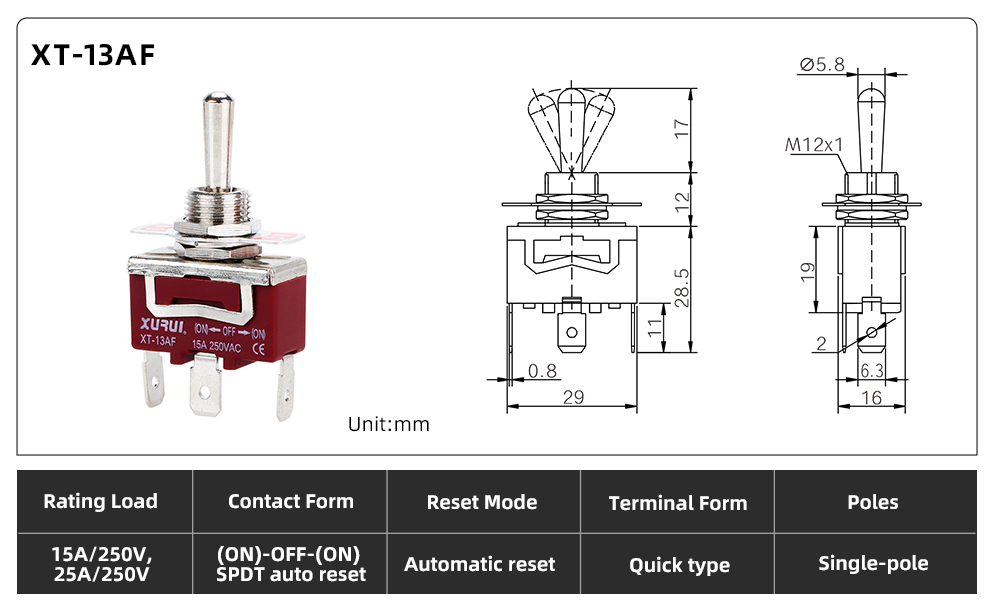

在购买拨动开关之前,您应该查看一些重要的规格,例如电流和电压条件、激活力、安装样式、连接器类型和户外条件。 XURUI 开关是一家值得信赖的制造商,提供详细的数据表,并可以定制产品,以专业的品质和关怀来满足您项目的确切需求。

批量订单、定制和供应商提示

在处理大型项目时,获得大量拨动开关可以为您省钱。 XURUI 开关供应商是提供定制服务的众多供应商之一,类似于不同的选择器颜色、标记或防漏密封件。 与您的提供商建立联系可以帮助您获得更优惠的价格、更快的运输和更好的专家支持。

常见问题解答

我可以用摇杆代替拨动开关吗?

您可以将拨动开关更换为翘板开关,但需要更换面板,因为开关具有不同的安装尺寸和形状。 也可能需要更改接线连接,以便它们适合刀片端部而不是支腿或螺钉。 确保新开关符合电气条件。

哪种类型在户外使用时使用寿命更长?

在室外使用时,拨动开关,尤其是防水或密封的拨动开关,往往比翘板开关使用寿命更长,因为它们更能防尘、防水和物理损坏。

我的应用需要具有防水等级的开关吗?

如果您的开关将暴露在水、雨或其他液体中,则最好使用防水拨动开关,这可能发生在海军或工业环境中。 这将确保开关安全并避免生锈。

结论

无论您选择翘板开关还是拨动开关,都取决于您的作要求、可用空间、您需要它持续多长时间以及您对效果外观的特殊品味。 拨动开关在工业、汽车和航海领域很受欢迎,因为它坚固耐用,提供物理输入,并且可以在恶劣的条件下工作。 另一方面,翘板开关非常适合家用和消费电子产品,因为它们看起来不错且易于使用。

看看 XURUI 开关供应商 如果您需要符合行业规范的可靠拨动开关。 由于其强大的设计、安全仪表和灵活的选择,它是艰巨工作的绝佳选择。