限位开关是交流还是直流?

限位开关在检测各种系统中的运动和控制作方面发挥着关键作用。选择正确的类型(交流、直流或双额定型)对于正常功能和安全性至关重要。本指南将帮助您了解交流和直流限位开关之间的区别以及如何选择适合您需求的限位开关。

快速答案 — 交流电、直流电或两者兼而有之

限位开关的额定值可以用于交流、直流或两者兼而有之。这取决于开关的设计和测试方式。有些开关专为处理交流电 (AC) 而设计,有些则为直流电 (DC) 而设计,有些则采用双额定值以安全地支持这两种类型。

为什么错误的限位开关可能是一个代价高昂的错误

使用错误的电压类型,开关可能会很快失效,甚至更糟。直流电路由于恒定电流而对触点施加更大的压力,从而导致过热、电弧甚至系统损坏。直流电路中的纯交流开关是早期故障的常见原因。

交流和直流限位开关之间的主要区别

他们如何以不同的方式处理电流

交流电流每秒交替并穿过零伏 60 次,这自然有助于在触点打开时熄灭电弧。然而,直流电流是恒定的,不会通过零,因此更难断裂,更容易引起电弧。

为什么评级不可互换

额定交流电压为 250V 的限位开关只能额定电压为 30V 直流电压。这是因为直流需要更宽的触点间距和更坚固的材料。请务必检查数据表,切勿假设交流和直流额定值可以互换。

触点磨损和电弧问题

直流由于其单向和连续流动而对触点造成更多磨损。这使得电弧更加强烈和持久,这就是为什么直流额定开关通常包含减少电弧损坏的功能。

如何判断限位开关是交流还是直流

检查标签或数据表

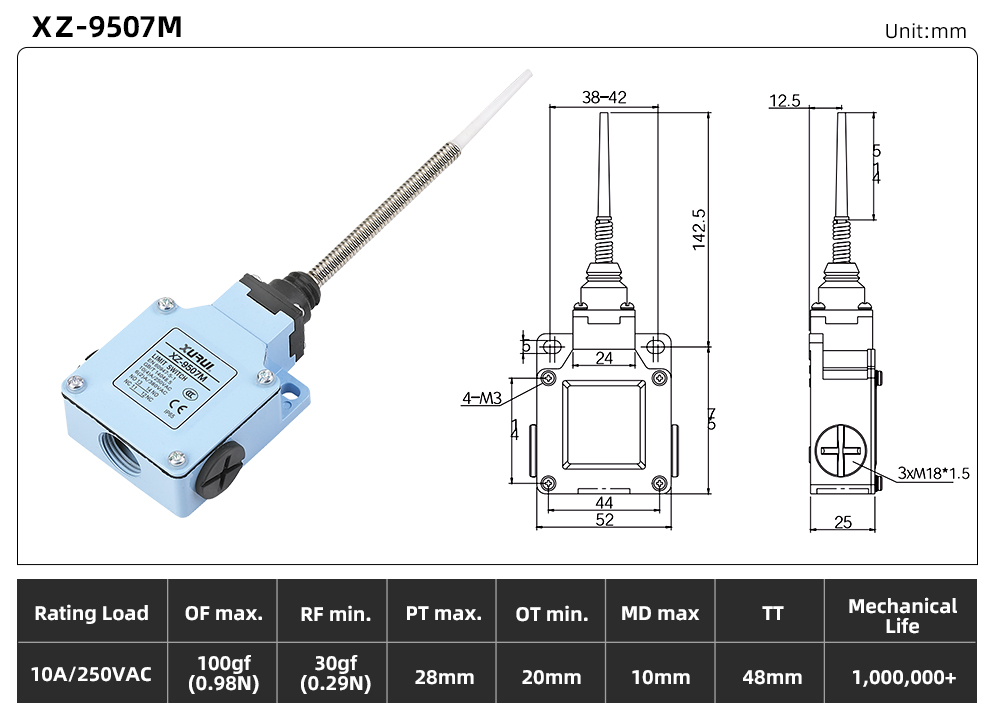

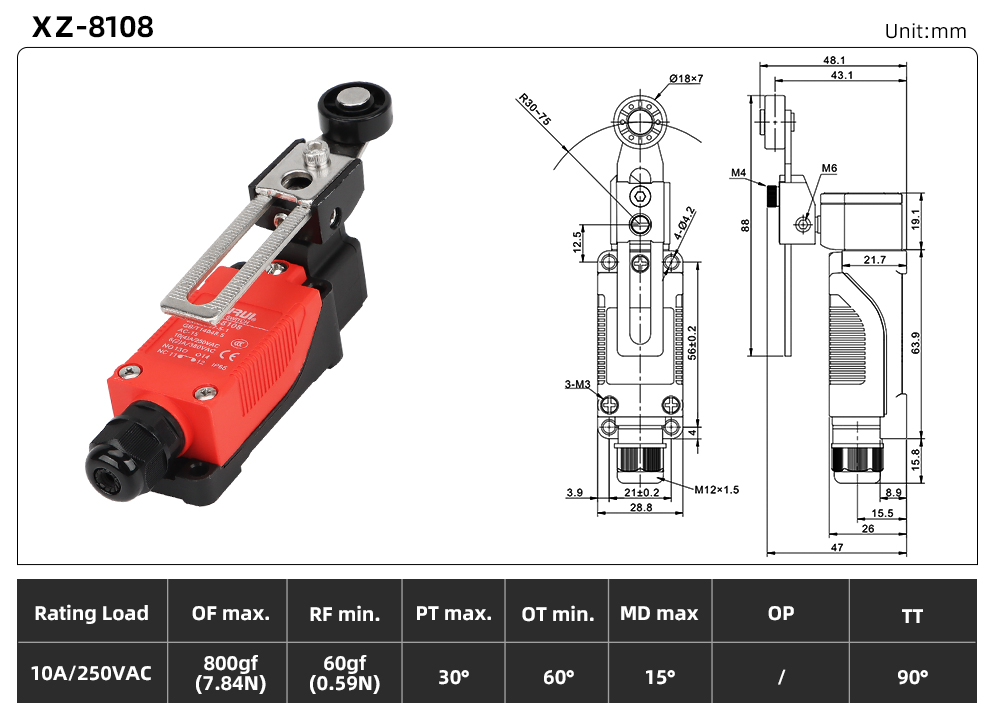

查看开关标签或制造商数据表,了解电压和电流额定值。它应明确说明开关是否适用于交流、直流或两者,以及最大电压和电流值。

寻找认证标志

寻找 UL 或 CE 等标志——它们证明它已经过正确电源类型的测试。此类认证还表明该开关符合电气安全标准。

双额定开关说明

双额定开关经过设计和测试,可在交流和直流下安全工作。它们提供了灵活性,但往往更坚固且价格稍贵。当设备可能在不同的电源类型下运行时,它们是理想的选择。

如何为您的应用选择合适的限位开关

将交换机与您的电源类型相匹配

首先确定您的系统是使用交流电还是直流电。选择专门针对该电源类型的额定值开关,以确保正常作和安全。永远不要猜测——电压类型很重要。

相关阅读: 限位开关有哪6种类型?

考虑电压和电流要求

电压和电流额定值与类型同样重要。即使是双额定开关也有局限性。确保额定值与您的应用相匹配,特别是对于大功率设备或控制电路。

防止直流电路中的电弧损坏

如果必须切换直流,请使用反激式二极管、消弧器或继电器等外部保护。这些组件有助于减少电弧并延长限位开关的使用寿命。

限位开关应避免的常见错误

假设所有开关都是通用的

并非所有限位开关都能同时处理交流和直流。使用错误的类型可能会导致快速磨损或故障。始终验证评级,而不是假设兼容性。

忽视环境因素

热量、灰尘、振动和湿气都会影响开关性能。如果您的环境恶劣或不稳定,请使用机柜或选择工业级交换机。

在高负载下使用控制开关

限位开关设计用于发送信号,而不是控制大功率负载。不要用它们直接切换电机或大电流——这就是接触器或继电器的用途。

现实世界的例子:交流与直流开关的使用

示例 1:输送系统中的交流限位开关

120V 交流供电的输送带使用限位开关来检测行程结束。一旦皮带到达末端,开关就会停止电机,防止机械损坏或产品错位。

示例 2:太阳能应用中的直流限位开关

在由 24V DC 供电的太阳能跟踪系统中,限位开关有助于检测完全倾斜或旋转。它向控制器发出停止运动的信号,保护面板和驱动系统免受超程的影响。

选择正确限位开关的最终提示

使用制造商指南

请务必阅读数据表。制造商准确指定他们的交换机可以做什么和不能做什么。这些信息比猜测或假设更可靠。

不要混合评级

切勿在直流系统中使用交流额定开关,反之亦然,除非产品是专门的双额定值。不匹配的使用会导致性能不可靠或失败。

如果不确定,请寻求专家帮助

如果您不确定,请咨询您的供应商、技术人员或工程师。简短的咨询可以防止以后出现代价高昂的错误或安全问题。

常见问题解答

Q1:我可以在直流电路中使用交流限位开关吗?

答:不安全。交流开关不是为直流恒流而设计的,可能会过热或发生故障。始终使用额定直流使用的开关。

Q2:所有限位开关都兼容交流和直流吗?

答:没有。只有专门标记为双额定值的开关才能安全地与两者一起使用。请务必在数据表中进行验证。

Q3:为什么交流和直流额定值如此不同?

答:直流电产生更多的电弧,因为它不像交流电那样通过零。这就是为什么直流开关需要更坚固的材料并且通常具有较低的额定值。

Q4:如果我使用错误类型的限位开关会怎样?

答:可能会导致开关故障、误触发、触点烧坏,甚至火灾隐患。

结论

选择合适的限位开关不仅关乎功能,还关乎安全性、可靠性和长期性能。无论您的系统在交流、直流还是两者上运行,请务必在安装前验证交换机的额定值。注意数据表、电压限制和环境因素。有了正确的信息,您可以避免代价高昂的错误并确保您的设备平稳运行。