固态继电器与普通继电器的区别

继电器是电子和机器人领域用于切换电气连接的基本组件,这些领域不断发展。在现有的所有类型中,最常见的是固态继电器 (SSR) 和普通继电器。我们将讨论这两种继电器之间的主要区别,以及使用每种继电器的最佳时间。

固态继电器和普通继电器的区别

本部分中的信息将帮助您了解这两种类型的工作原理。

固态继电器 (SSR) 的定义

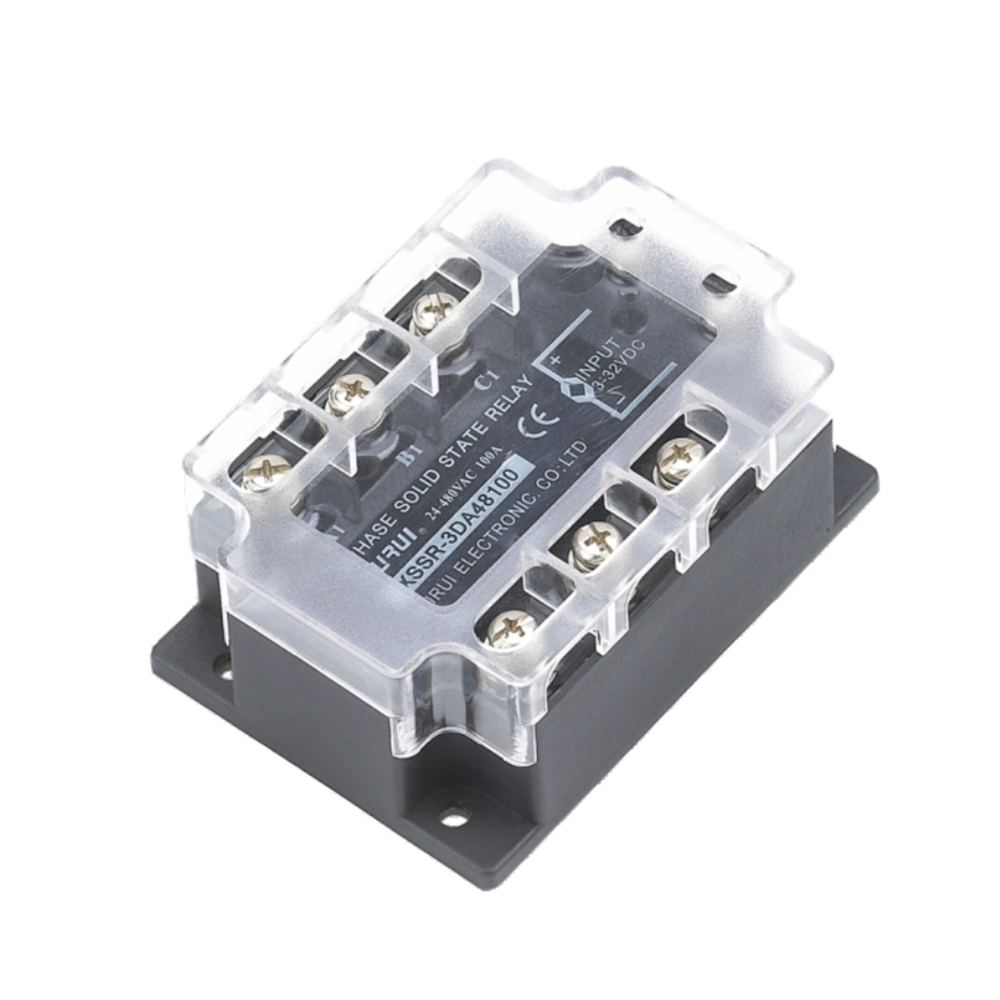

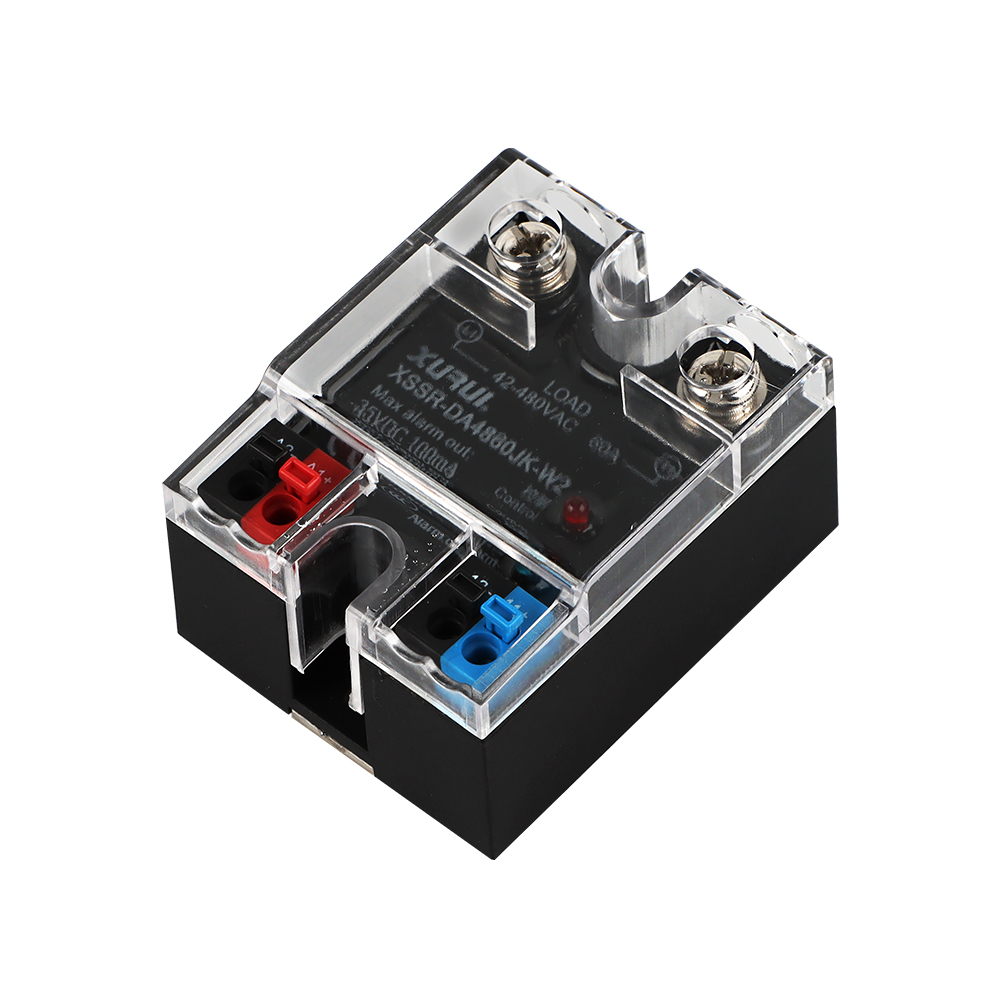

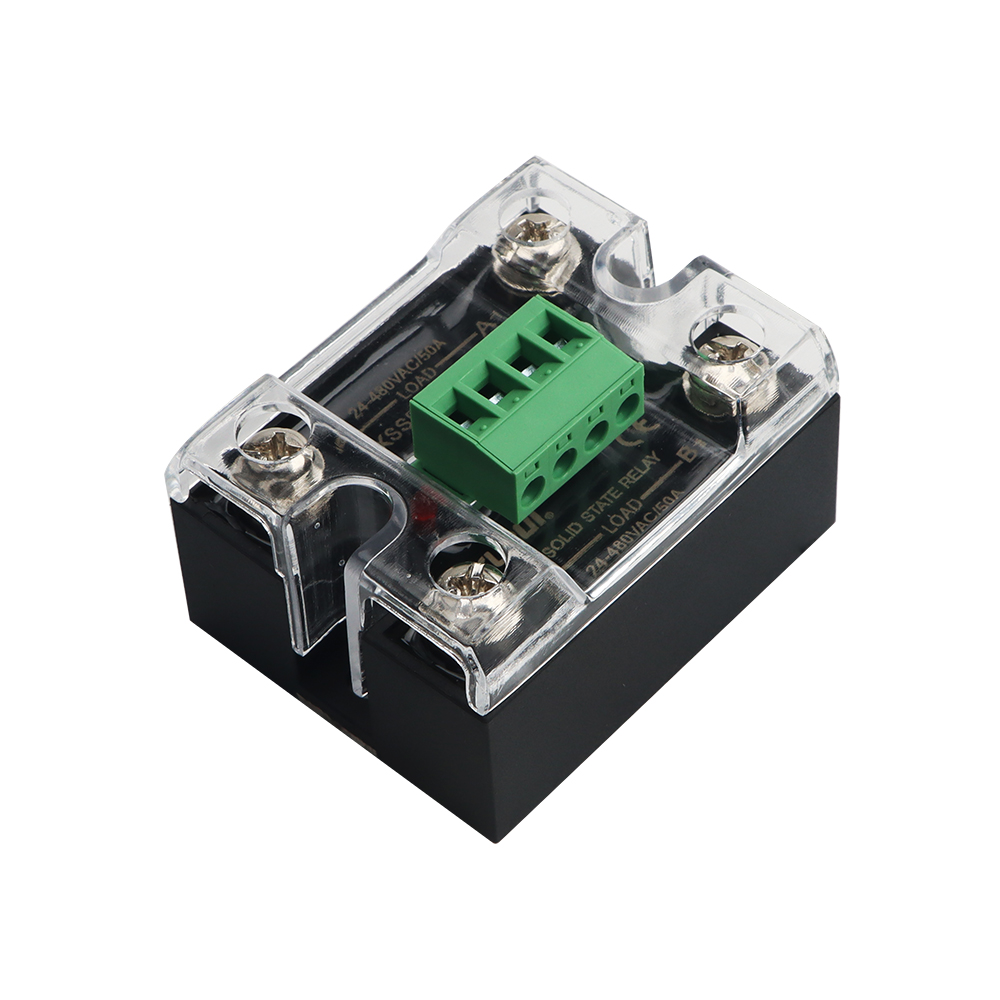

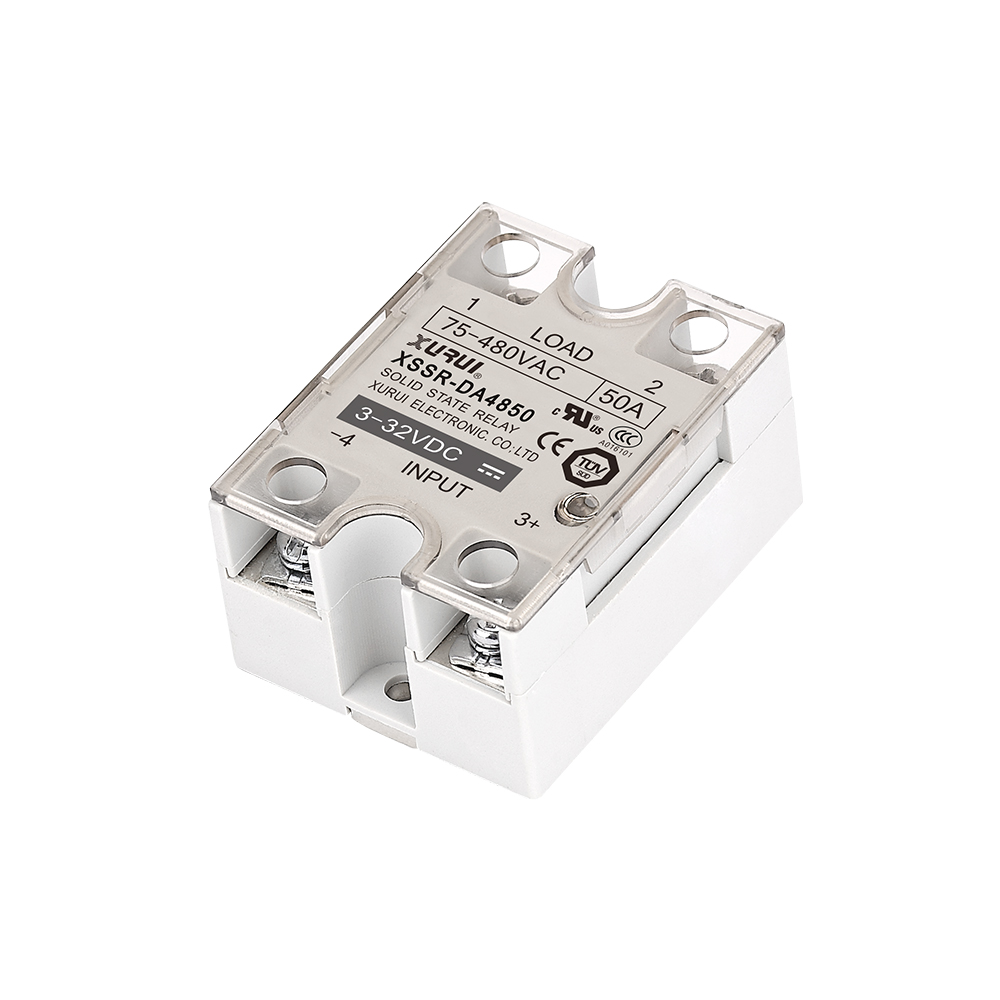

电路由晶应管、双向可控硅开关或固态继电器中的 MOSFET 等半导体控制,固态继电器是一种电子开关器件。SSR 与机械开关不同,因为它们没有任何移动走廊。这使得切换安静、无钥匙且非常可靠。

SSR 通常是需要快速切换、降噪和长期耐用性的任务的最佳选择。这些继电器将由著名的固态继电器制造商制造,可持续数百万轮而不会断裂。

普通继电器(机电继电器)的定义

当您使用电磁铁移动常规或机电继电器 (EMR) 上的金属触点时,电路可以打开或关闭。人们可以通过发出的咔哒声来欣赏这些开关。因为它们很便宜,所以它们经常用于人工和加工小部件。

另一方面,EMR 会随着时间的推移而磨损,因为它们会四处移动,与固态继电器相比,这限制了它们的开关频率和寿命。

核心工作原理比较

从本质上讲,主要区别在于断路器如何打开和关闭。EMR 依靠机械搅拌来打开半导体开关,而固态继电器则使用电信号来做同样的事情。

这种差异对性能、保护性、可稳定性和可采用的作范围有直接影响。与具有丰富经验的固态继电器制造商合作将帮助您获得符合系统要求的精确性能规格。

固态继电器和普通继电器之间的主要区别

关于基础知识就够了。让我们并排看看这两种类型的继电器,看看您在现实生活中使用的基本功能。

开关机制:非接触式与机械式

固态继电器使用半导体进行开关,因此无需物理接触即可工作。这消除了触摸反弹和电弧,这是 EMR 的常见问题。另一方面,普通继电器是物理打开和关闭的连接,随着时间的推移会导致磨损和击穿。

因此,SSR 非常适合寿命至关重要的高周期作。

性能和耐用性

固态继电器的一大优点是使用寿命长。由于它们没有任何工作部件,SSR 的使用寿命要长得多——在理想条件下,它们可以持续超过 1 亿发子弹。大多数机械开关只能处理 1 到 1000 万匝。

顶级固态继电器制造商将使用强大的部件和热管理功能,以提高性能和预期寿命。

响应时间和开关速度

SSR 的响应时间优于 EMR。因为它们是机械的,所以 EMR 在打开和关闭时会暂停,但固态继电器通常在微秒内打开和关闭。这对于机器人、高速自动化系统和协同运行的系统尤为重要。

电噪声和抗振性

固态开关不会产生电火花或爆裂声,因为它们不会接触任何东西。这使得它们非常适合不需要噪音的地方和容易振动的系统。

因为它们是机械的,所以常规开关在这些条件下更容易颤动或失效。

尺寸、安装和外形尺寸

SSR 通常采用更小、更灵活的形式。由于它们较小,因此可以通过多种方式安装,例如 DIN 导轨或 PCB 上。因为它们有线圈和触摸臂,所以 EMR 往往更大。

固态继电器具有纤薄的基本设计,因此更容易安装到空间有限的系统中。

应用场景和行业用例

使用SSR还是EMR取决于情况。本节提供有关每种类型性能最佳的环境的详细信息。

固态继电器的理想用例

这就是固态开关的用途:

·工厂自动化系统

·天气控制和暖通空调装置

·医疗用设备和小工具

·制作食品的设备

·灯光控制系统

在这些情况下,机器必须安静、准确且耐用。SSR 在所有这些方面都表现出色。对于这些领域中的每一个,您可以信赖的固态继电器制造商都会制造恰到好处的模型。

当普通继电器更合适时

即便如此,在以下情况下,定期运行可能仍然更好:

·成本是一个很大的担忧。

·开关频率低。

·负载只是被动的。

·需要有声音的点击输入(例如,家用工具)。

EMR 在需求低且开关周期少的系统中可能足够了,因为它们很简单。

行业示例:从自动化到消费电子产品

固态开关提供自动产品线所需的快速开关和责任,以减少超时。另一方面,普通继电器经常用于低频系统,类似于洗衣机、电源和报警系统。

重要的是从可靠的固态继电器制造商处获得继电器,并确保它与您的工作和周围环境配合良好。

成本、维护和效率比较

SSR 最初可能成本更高,但从长远来看,它们是值得的,因为它们高效且需要最少的维护。数字细分如下。

初始投资与长期成本

大多数时候,固态开关一开始的成本更高。然而,随着时间的推移,如果维修次数和维护次数减少,总拥有成本会显着降低。EMR 最初可能更便宜,但需要更频繁的维修和更换。

寿命和故障率

如果放置得当,SSR 的故障率非常低,在低应力环境中可以使用 20 年以上。因为它们有移动部件,所以 EMR 更有可能发生故障。

如果您从信誉良好的固态继电器制造商那里购买 SSR,您可以确定它会做工精良且使用寿命更长。

维护要求和停机风险

为了防止接触磨损和生锈,需要定期检查和维修电子病历。另一方面,固态开关不需要太多维护,从而减少了系统停机时间和劳动力成本。

技术注意事项和安装技巧

仅仅查看规格以选择正确的链接是不够的。以下是安装和设置在现实世界中使用的交换机所需了解的信息。

负载兼容性:AC/DC、电阻式与电感式

始终为作业使用正确的连接类型。不同的固态开关最适合其他类型的负载,例如交流或直流。为了帮助损坏,迷人的负载还带有缓冲电路或过零开关功能的 SSR。

可估价的固态继电器制造商将提供数据表和专业支持,以帮助您将继电器与货物类型相匹配。

电压和电流条件解释

选择能够处理正确功率和电流的开关至关重要。任何开关,无论是固态开关还是机械开关,如果装得太满,都可能沸腾、弯曲或失效。始终考虑根据货物和周围环境进行降额。

保护电路:缓冲器、保险丝和二极管

外部缓冲电路有助于防止磁负载发生电压尖峰。保险丝和反激式二极管可保护开关和任何连接的设备免受电气损坏。如果您希望固态继电器尽可能长时间地使用,这些非常重要。

安装和接线的最佳实践

·确保 SSR 具有正确的散热器。

·避免使用松动的电线或安装不良的组件。

·将接收器放在空气流通良好的盒子中。

·在肮脏或潮湿的地方,使用保护罩。

当专业的固态继电器制造商制造一个时,他们通常会包含额外的零件和安装说明,以使其更容易。

解决问题和购买

在购买或更换继电器之前,请了解其最普遍的问题以及如何预防这些问题。

为什么我的继电器过热?

过热通常是由于顺风差、功率过大或散热不足而发生的。始终检查您使用的固态继电器是否适合这项工作,并且您是否按照制造商告诉您的方式放置它。

SSR 无法正确切换 – 检查内容

·确保输入信号强度正确。

·检查电压和负载线。

·检查 SSR 是否因功率或电流过大而损坏。

您可以信赖的大多数固态继电器制造商都会提供调试技巧和技术支持来提供帮助。

继电器选择中的常见错误

·在直流负载上使用交流额定 SSR 时

·不估计当前容量

·忽视了减少热量的需要

·从廉价、低质量的公司购买

为避免这些错误,请仅从您可以信赖的固态继电器制造商处购买继电器。

结论

固态继电器(SSR)和普通机电继电器(EMR)都有其优势和理想的应用。SSR 具有卓越的耐用性、更快的开关速度和安静的运行,非常适合高速自动化、医疗设备和需要最小噪音的环境。然而,EMR 具有成本效益,适用于开关周期不频繁的低频应用。虽然 SSR 的初始成本可能较高,但从长远来看,它们的使用寿命长、维护需求低且可靠性使其成为明智的投资。为了确保最佳性能,根据您的要求选择合适的继电器并从值得信赖的制造商处购买至关重要。