如何连接固态继电器

固态继电器 (SSR) 是一种安静、快速且可靠的使用低压信号切换高压设备的方法。无论您是自动化加热器、使用 Arduino 控制灯,还是构建工业面板,本指南都将引导您清晰、自信地了解您需要了解的所有内容。

什么是固态继电器,它是如何工作的?

固态继电器与机械继电器:有什么区别?

机械继电器的工作原理类似于微小的金属开关。当电磁线圈拉动内部触点时,它们会发出咔嗒声打开和关闭。但随着时间的推移,机械部件会磨损、产生噪音并变得不那么可靠。

相比之下,固态继电器没有移动部件。他们使用双向可控硅开关或晶体管等半导体来进行开关。没有咔嗒声,没有弧线,没有弹跳。这意味着更长的使用寿命、更快的开关和更安静的运行。

SSR 的基本组件和内部工作原理

在 SSR 内部,有两个关键方面:输入和输出。当控制信号发送到输入侧(通常是低压直流电)时,它会激活光耦合器。这可以安全地触发输出侧的开关元件,例如双向可控硅开关或 MOSFET。

由于控制侧和输出侧是光学隔离的,因此即使在切换高压负载时,低压设备(如 Arduino)也能保持安全。这就是 SSR 在敏感电子系统中如此受欢迎的原因之一。

固态继电器的常见用例

您会在各种地方找到 SSR:工业自动化、3D 打印机、HVAC 系统、家用电器。它们非常适合开关灯、风扇、加热器和电机。制造商经常使用它们让微控制器安全地控制高压交流设备。

了解固态继电器的端子

现在您已经了解了 SSR 的工作原理,让我们动手实践一下。了解电线的连接位置对于避免混乱和损坏至关重要。

输入侧(控制端子和触发电压)

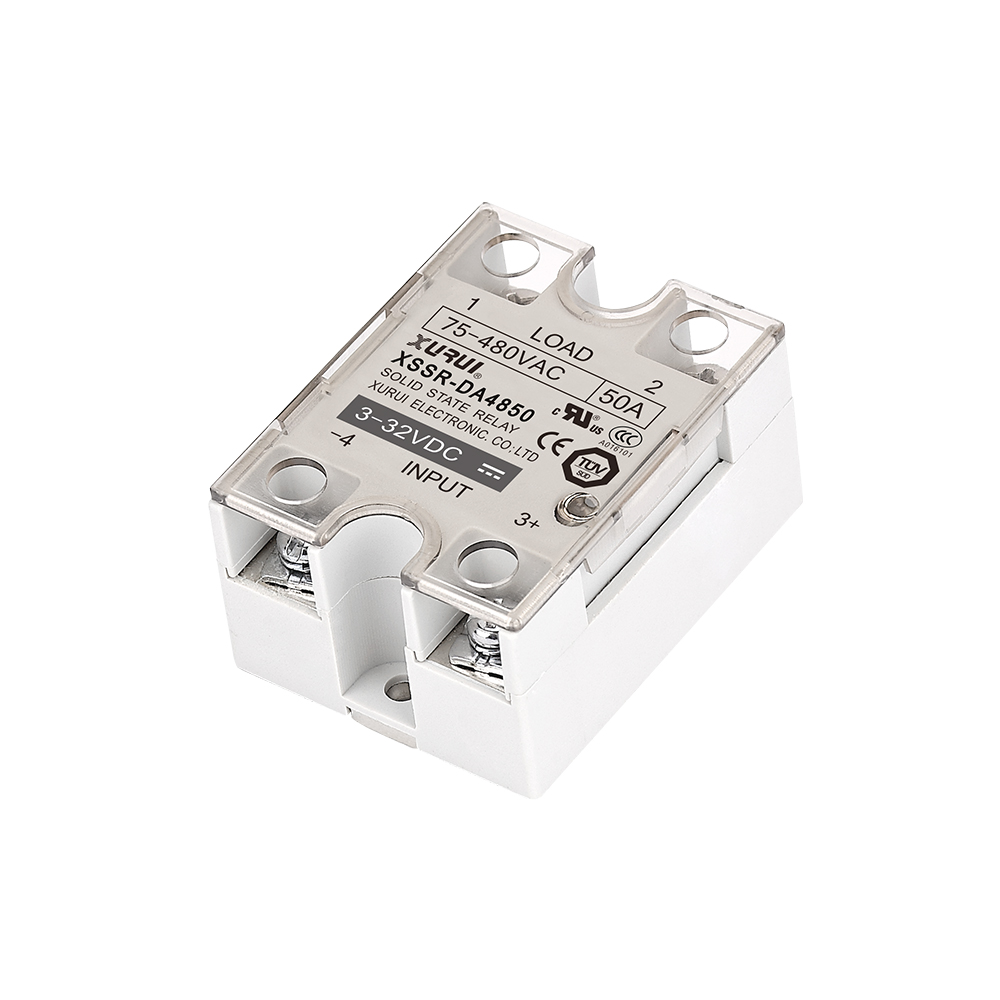

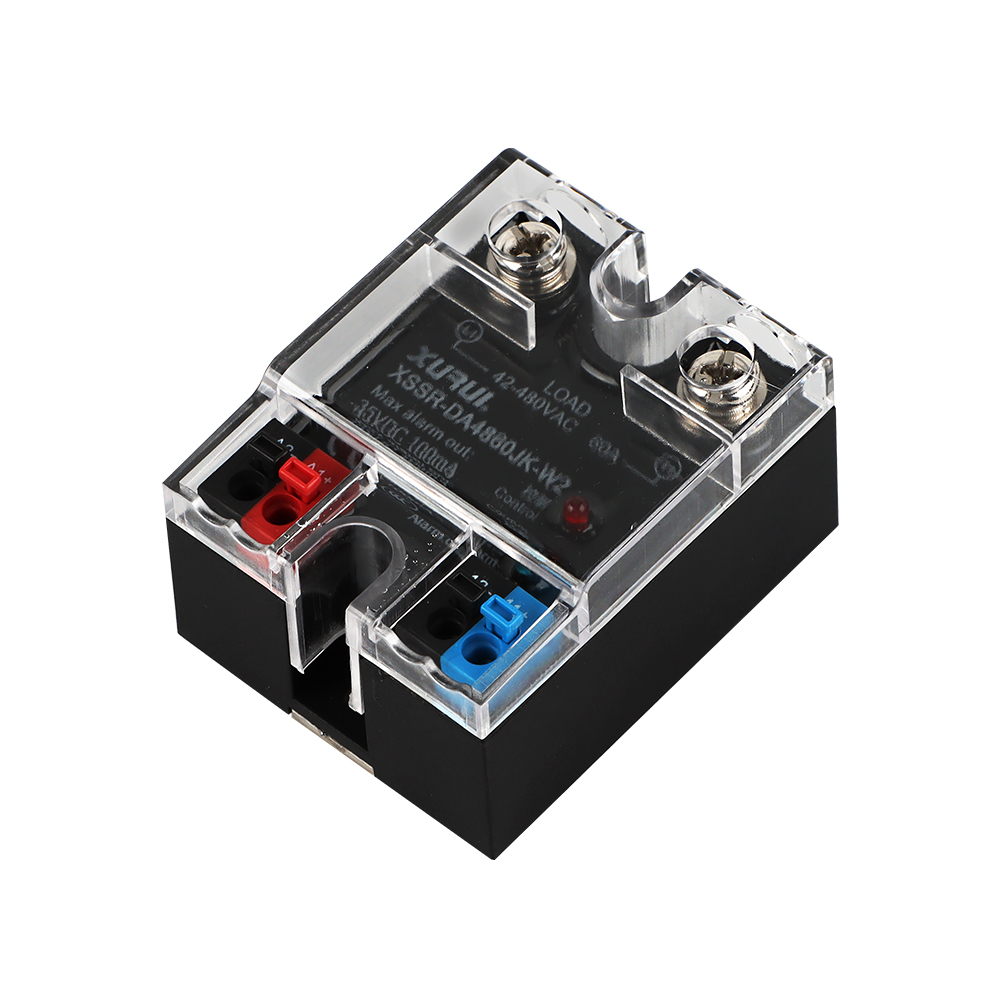

输入侧(通常标记为“+”和“−”或 3 和 4)接收控制信号。它可以是来自 Arduino 的 5V 信号或来自 PLC 的 24V 信号。请务必检查继电器的输入电压范围。如果不匹配,SSR 根本无法打开。

输出侧(负载端子和开关电路)

输出侧(通常标记为 1 和 2)是电力流向负载的地方。这是打开或关闭交流或直流负载的地方。对于直流负载,请注意极性。对于交流负载,极性通常不是问题。

解释端子标签和极性

每个 SSR 都有标签,但并非每个标签都是相同的。有些使用数字,有些使用符号。关键是知道哪一侧控制电路,哪一侧承载负载。如有疑问,请阅读数据表。

选择正确类型的固态继电器

Before you start wiring, you need to make sure you’ve got the right type of SSR for your project. Let’s break it down.

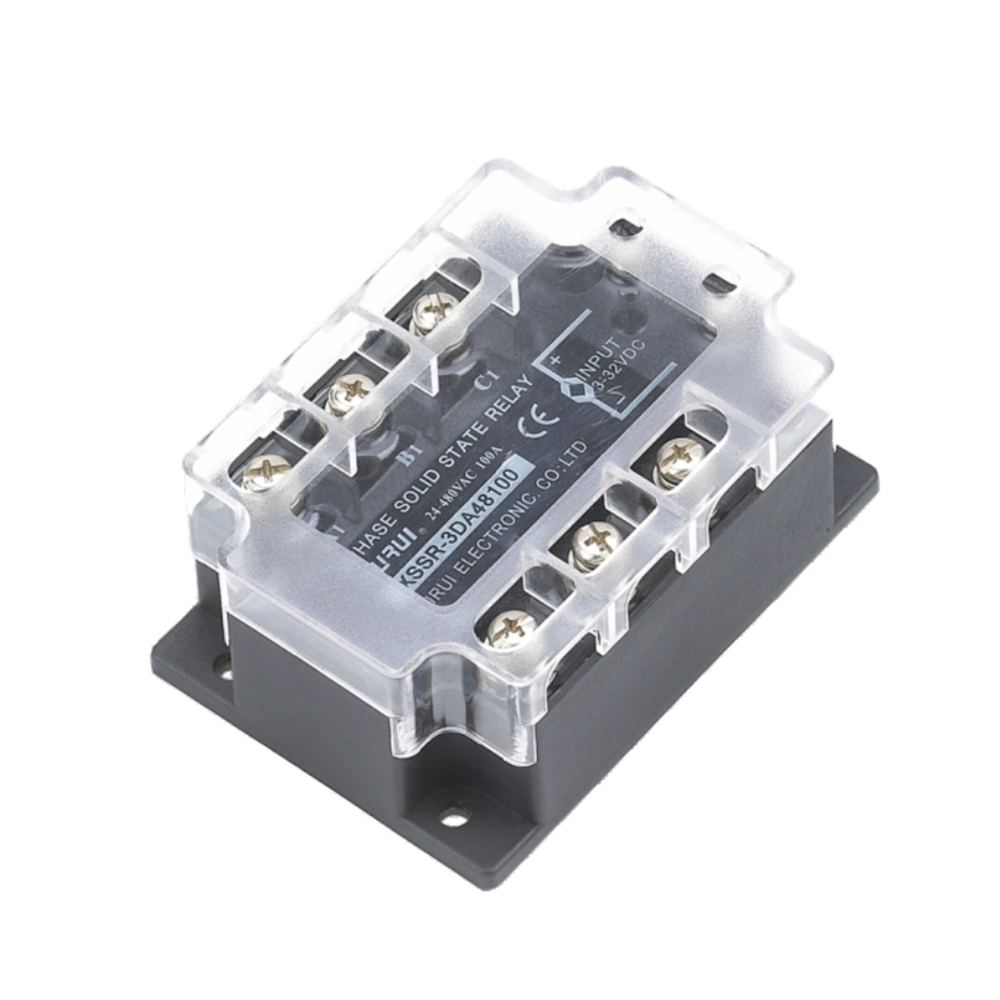

AC-AC、DC-AC、DC-DC – 您需要哪一个?

将您的 SSR 与您正在使用的信号类型和您要切换的负载相匹配。如果您使用直流控制信号来切换交流负载(非常常见),请选择 DC-AC SSR。对于 DC-DC 或 AC-to-AC 需求,请相应选择。

根据负载类型选择SSR(电阻与电感)

加热器和灯是电阻负载。电机和电磁阀是电感式的。电感负载需要格外小心,例如缓冲电路或反激式二极管,以保护 SSR 免受电压尖峰的影响。

需要考虑的关键规格:电压、电流、触发范围

检查三个关键规格:输入电压(您的控制器可以驱动它吗?)、输出电压/电流(它可以处理您的负载吗?)和开关类型(某些 SSR 在交流交零点时切换)。

相关阅读: 固态继电器适合您吗?

如何逐步连接固态继电器

你的继电器被选中了吗?太好了,让我们连接起来吧。慢慢来,仔细检查一切,你会没事的。

您需要的工具、电源和接线材料

您需要 SSR、螺丝刀、适当规格的电线、万用表,也许还需要散热器或缓冲器。使用交流电路时,安全手套是一个加分项。

如何安全地连接控制侧(Arduino、PLC 等)

Connect your low-voltage control signal to the SSR’s input terminals: digital pin or control output to “+”, ground to “−”. If your controller doesn’t provide enough voltage, use a transistor or driver.

How to Wire the Load Side to an AC or DC Device

将负载与 SSR 的输出串联。例如:交流火线连接到 SSR 端子 1,端子 2 连接到您的灯,然后回到中性线。对于直流电,连接正确的极性。切勿像开关一样在两个 SSR 端子上连接负载。

为电路供电前的最终检查

确保没有松动。测量控制端子两端的电压。确认您的负载电流不超过 SSR 的额定值。然后打开电源并测试它。

常见场景的接线图示例

这里有一些实际示例,可帮助您了解这一切的实际效果。

将 SSR 连接到 Arduino 和交流灯

数字引脚到 SSR +,Arduino GND 到 SSR −。在输出侧,火线连接到端子 1,端子 2 连接到灯泡,然后连接到交流中性线。当 Arduino 输出高电平时,灯亮起。

使用带有SSR的PLC驱动直流电机

将 PLC 输出连接到 SSR 输入,电流/电压适当。输出端子与电机和直流电源串联。在电机上添加一个反激二极管以抑制尖峰。

用于控制加热器的手动开关和 SSR 设置

在电源和 SSR 输入之间连接手动开关。在负载侧,像使用普通开关一样通过 SSR 输出连接加热器。简单、安全、有效。

安全可靠 SSR作的技巧

一些小事对于使您的 SSR 设置持续时间更长、工作得更好大有帮助。

使用适当的电压和电流额定值以确保稳定性

选择额定值至少比预期负载高 20-30% 的 SSR。如果您的加热器消耗 8A,请选择 10A 或 15A SSR。这种开销可以防止热应激并延长使用寿命。

为高于 5A 的负载添加散热器

SSR 会变热,尤其是在连续负载的情况下。将继电器安装到金属面板上或使用专用散热器。遵循数据表的散热建议。

使用缓冲器或反激式二极管保护您的电路

缓冲器可帮助交流 SSR 在不产生电弧的情况下切换感性负载。对于直流,负载两端的反激式二极管可防止电压尖峰烧毁继电器。

使用实际负载进行测试——而不仅仅是万用表

SSR 通常需要实际电流才能正常运行。如果它没有发出咔嗒声或亮起,请不要认为它坏了。插上实物,在工况下观察。

连接 SSR 时要避免的常见错误

让我们避开这些初学者陷阱,为您省去一些挫败感。

混淆输入和输出端子

一侧是控制,另一侧是开关电源。翻转它们,什么也没用——或者更糟糕的是,有东西烧焦了。检查标签和图表。

使用过小的触发信号

3.3V 信号无法驱动 12V 额定 SSR。使用逻辑电平 SSR 或在控制和继电器之间添加晶体管开关。

忽略散热要求

没有散热器?期待失败。热失控是真实存在的。如果继电器摸起来很热,则需要冷却解决方案。

省略电路保护(保险丝、断路器等)

SSR 不能保护您的负载,而是您必须保护。安装与高压接线一致的保险丝或断路器。

故障排除:为什么我的 SSR 无法正常工作?

SSR给你带来麻烦?以下是诊断方法。

SSR 未打开 – 检查触发电压和极性

测量控制输入两端的电压。如果它在范围内但没有任何反应,请检查极性。直流输入关心哪一侧是 +,哪一侧是 −。

SSR Always On – 了解泄漏和负载类型

一些 SSR 即使在关闭时也会泄漏小电流。对于低功率负载,这可能足以让它们保持昏暗或旋转。添加一个泄放电阻器将其排出。

负载闪烁或意外关闭

您的连接可能不良或控制电压降。确保端子紧固且控制器输出稳定。

继电器过热或过早失效

电流被低估、没有散热器或通风不良?先解决这些问题。还要检查电机或变压器是否有电感尖峰。

相关阅读: 解决实际问题的 15 个固态继电器故障排除技巧

常见问题解答(FAQ)

Q1:我可以将固态继电器直接连接到 Arduino 或 Raspberry Pi 吗?

是的,只要 SSR 接受 3.3V 或 5V 输入。否则,请使用驱动器晶体管或光隔离模块。

Q2:我如何知道我的 SSR 是交流型还是直流型?

查找标签或数据表符号。正弦波表示交流电;直线或“+/-”表示直流。

Q3:SSR 需要散热器吗?

对于 5A 以上的任何东西,是的。否则,它们会过热并失效。

Q4:为什么我的SSR无法完全关闭?

漏电流或感性负载是常见原因。添加缓冲器或泄放电阻器。

Q5:SSR可以切换电机或风扇吗?

是的——如果它们的额定值是感性负载。请务必添加反激式二极管或缓冲器等保护。

结论

固态继电器提供了一种智能、高效和可靠的方法来使用低压逻辑控制高压电路。通过了解它们的工作原理、选择正确的类型并正确接线,您可以充分利用它们的速度、静音和耐用性。无论您是楼宇自动化面板的工程师还是尝试微控制器的业余爱好者,掌握 SSR 都会打开一个充满安全、强大开关可能性的世界。慢慢来,遵循最佳实践,您将立即充满信心地进行切换。