切换开关的综合指南:类型、用途及更多

拨动开关对于控制电路中的电源至关重要。本指南向您展示了类型、用途、安装和维护,以帮助您选择合适的。

什么是拨动开关?

拨动开关是一个简单但非常有用的电气部件。将控制杆移动到不同的位置可以让您轻松调节电路。

定义和核心功能

拨动开关是一种手动电气开关,其具有来回移动以打开或关闭电路的杠杆或手柄。该设备使用户可以轻松停止或改变电流。拨动开关与按钮开关不同,因为它们包括一个单独的杠杆,该杠杆保持在所选位置,直到再次更换。这会为您提供明确的触觉反馈。

拨动开关连接或断开内部端子以调节一个或多个电路。它的主要工作是让您轻松可靠地作电气设备或设备。

相关阅读: 翘板开关和拨动开关的区别

关键部件及工作原理

拨动开关的主要部件是拨动杆(或执行器)、开关外壳、内部触点和电气端子。当您轻弹拨动杆以关闭电路时,内部触点要么接触,要么分开以断开电路。这种作通常使用机器完成,但使用电气走廊(例如发光开关中的 LED)可能会做得更好。

支撑拨动开关工作原理的介绍性思想很简单:移动开关会物理改变连接的位置,从而打开或关闭电路路线。一些拨动开关具有转瞬即逝的动作,这意味着当您松开开关时,开关会弹回。其他的则具有持续动作,这意味着开关保持在开关位置。

拨动开关的常见类型

有许多不同类型的拨动开关可以满足不同的电气和机械用途。因为它们可以产生多种效果,因此它们可用于入门和复杂电路。

SPST、SPDT 和 DPDT 开关

要选择合适的拨动开关,您需要了解多种类型:

SPST(单刀单掷): 这是最简单的拨动开关。它用作控制一个电路的介绍性开/关开关。它有两端,可以在连接和分离之间切换。

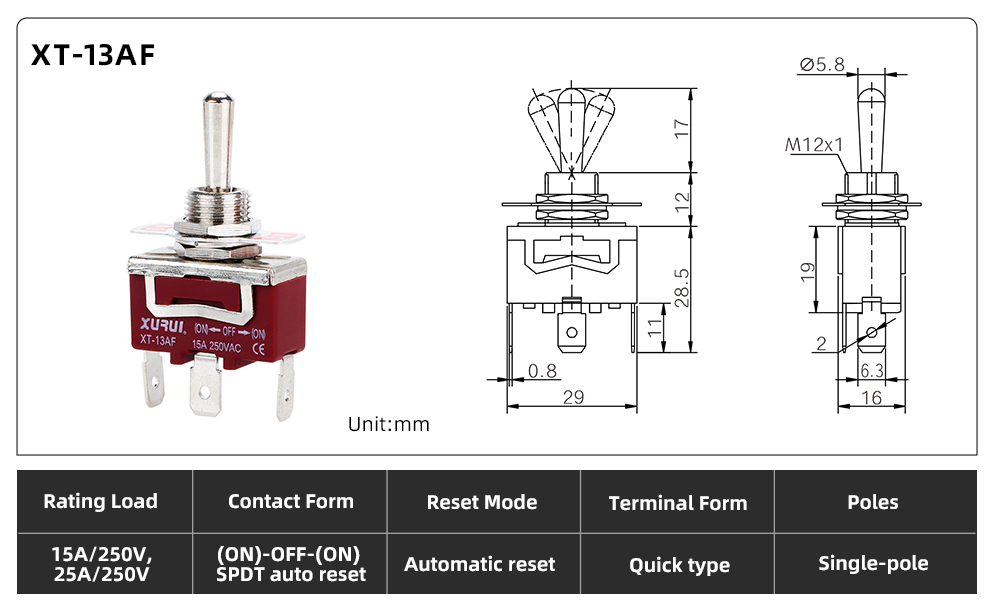

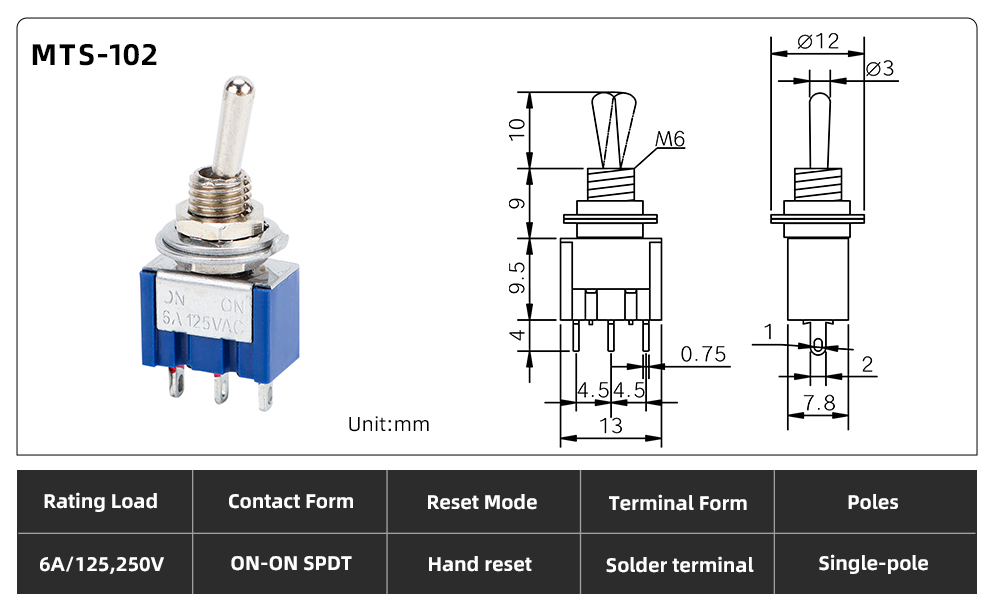

SPDT(单刀双掷): 这种有三个输出,可以切换两个电路之间的连接,这使其具有ON-ON功能。它经常用于在两个独立的劳动力或电源之间切换。

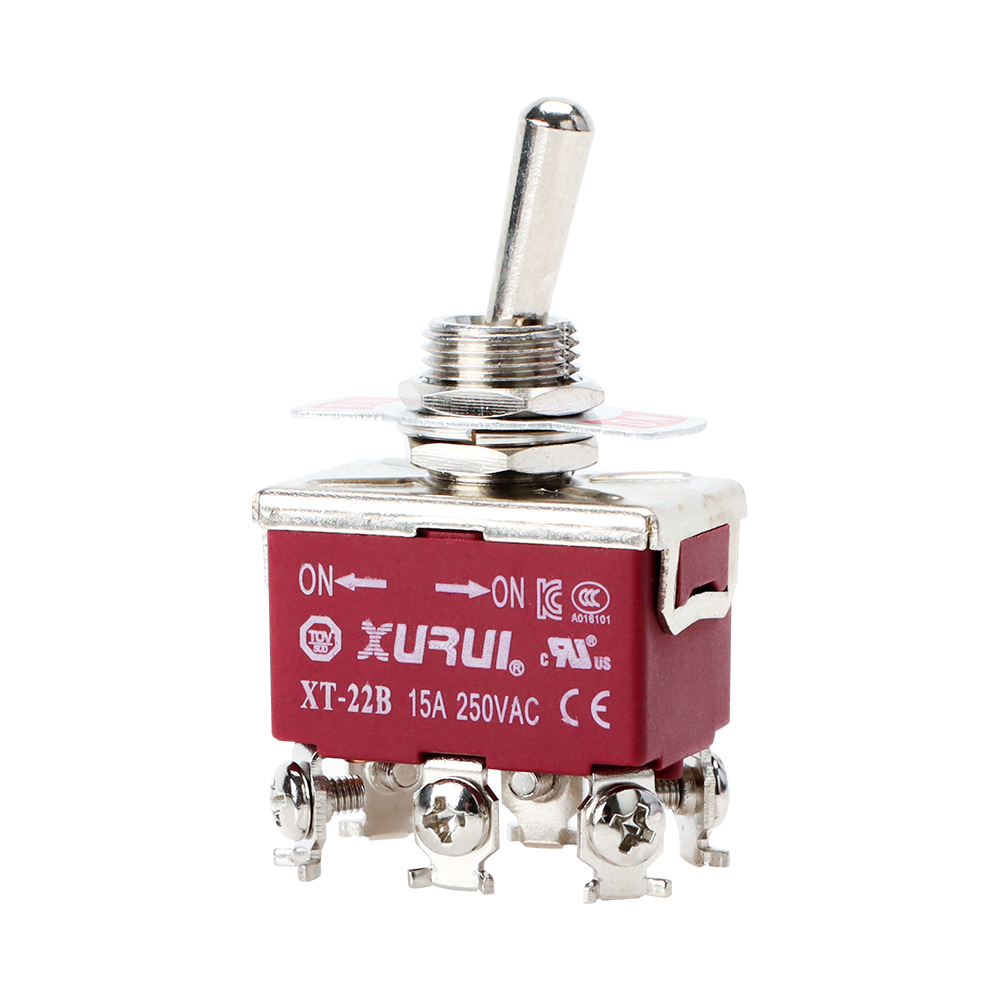

DPDT(双刀双掷): DPDT(双刀双掷)开关有六个输出,同时控制两个不同的电路。它通常用于改变电机的方向或复杂的开关系统。

开关有多种类型,您选择的类型取决于您的电路需求。

瞬时类型与维持类型

切换开关后的工作方式也会发生变化:

瞬时拨动开关: 当您松开此开关时,它会自行回到原来的位置。它用于需要短时间打开和关闭的东西,例如喇叭按钮或复位开关。

维护拨动开关: 此开关保持在切换位置,直到您用手重新打开它。当需要稳定的开/关状态时,人们经常将其用于电源开关或照明控制。

专业选项:发光、防水、锁定

除了基本需求外,还有许多其他类型的拨动开关是为满足特殊需求而制造的:

发光拨动开关: 这些开关带有内置 LED 或白炽灯泡,当开关打开时会亮起,为您提供清晰的视觉反馈。很多人在汽车仪表板和控制面板中使用它们。

可能防漏的拨动开关: 这些开关包含密封件和保护涂层,可防止水和湿气进入,使其最适合困难的人工、海洋和室外环境。

锁定拨动开关: 它们包含一个锁定机制,可防止它们被意外切换。这在高威胁或敏感情况下增加了新的安全性。

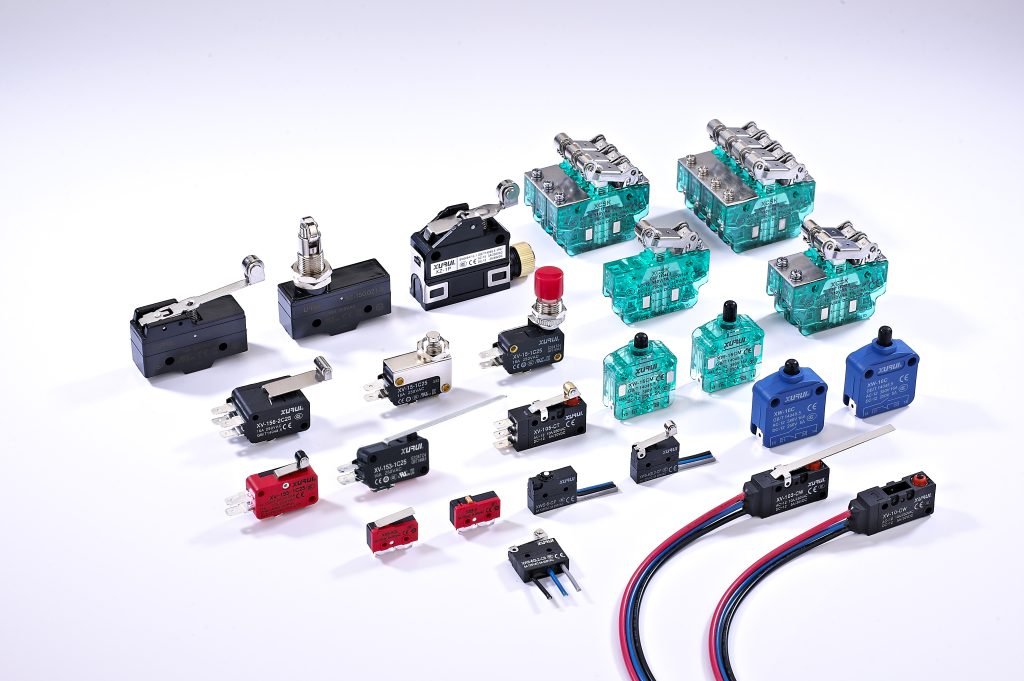

XURUI 开关有多种耐用且可靠的拨动开关可供选择,您可以查看这些拨动开关以了解有关这些高质量、专用开关的更多信息。

跨行业的典型应用

由于拨动开关易于使用且可靠,因此可用于许多不同的领域。它们是电气控制的流行选择。

汽车和船舶用途

拨动开关在汽车业务中非常重要,用于调节灯光、启动发动机和其他事情。驾驶者还可以流畅地使用拨动开关来显示独家功能。同样,防漏和抗侵蚀拨动开关也用于海上环境,以修改舱底泵、导航灯和不同的系统,确保它们在困难条件下可靠工作。

工业和机械控制

在制造商中,拨动开关用于调节输出、电机、传送带和安全系统。它们非常适合重型环境,因为它们坚固耐用,有多种不同的形状和尺寸,并且易于跟上。人工使用的拨动开关可以承受更大的电流和电压,符合安全法规,并在恶劣的环境中工作,包括灰尘、湿度和振动。

消费电子产品和 DIY 系统

拨动开关是一种简单的系统,用于调节消费电子产品和业余爱好者作的电路。拨动开关的触觉反馈和视觉信号使其更易于使用,无论是 DIY 放大器、机器人还是智能家居小部件。许多自己做事的人喜欢拨动开关,因为它们易于触及和接线。

如何选择合适的拨动开关

在选择合适的拨动开关时,您需要考虑电气和物理元件。选择合适的选项可以保证安全性,取决于重量、材料,并为您的应用提供最佳性能。

电流、电压和货物状况

要选择正确的拨动开关,您需要知道您的作需要多少功率。确保开关可以处理比电路最大负载更大的电流和电压。但是,如果您加载拨动开关,它可能会变得太热、磨损。

杆/投配置和电路需求

查看您的电路,看看您需要多少杆和投掷。如果您需要基本的开/关功能,SPST 拨动开关就足够了。但如果您需要任何更复杂的东西,您可能需要 SPDT 或 DPDT 开关。考虑一下您是否需要临时或持续的活动,以及是否需要任何特定特性,例如防水或照明。

安装方式、尺寸和耐用性因素

查看项目的物理限制。有三种放置拨动开关的方法:在面板上、在 PCB 上或表面上。另外,请考虑尺寸和形式以确保其合身。对于长期责任,外壳的材料、密封程度以及机械走廊的使用寿命等影响非常重要。

安装和接线基础知识

拨动开关在正确安装和接线时可以安全、良好地工作。遵循建议的程序可以降低出现问题的可能性并使开关的使用寿命更长。

工具和安全提示

在放入拨动开关之前,请务必关闭电源,以免受到电击。使用隔离的剥线钳、螺丝刀和钳子。护目镜可保护您的眼睛免受飞溅的火花或碎片的伤害。

常见开关类型的基本接线方法

要连接 SPST 拨动开关,您需要将负载线连接到一个端子,将电源线连接到另一个端子。接线 SPDT 和 DPDT 开关可能会更困难,因为您需要确切地知道电路路由的工作原理。接线原理图可以帮助您避免接线错误,从而导致短路或损坏。

为了便于故障排除,请在连接电缆时标记电缆。接线后,在打开电路之前,使用万用表检查耐用性和功能是否正确。

维护和常见故障排除

定期维护可以防止拨动开关突然发生故障,并使其使用寿命更长。能够解决常见问题意味着停机时间会更少。

识别磨损或连接问题

灯光颤动、零星功能、过热或拨动开关松动都是拨动开关可能需要修理或更换的迹象。连接或外站的侵蚀可能会使影响效果更差,特别是在粘性或海洋条件下。

清洁、更换或升级吸头

使用电触点清洁剂清洁触点以去除污垢和氧化是定期维护的一部分。如果开关无法修复,最好的办法是换一个新的。尽管如此,如果您在户外或进行重型工作时使用拨动开关,升级到高级或防漏骨头可能会使其工作时间更长、使用寿命更长。

质量标准和合规性

选择符合既定规范的拨动开关可确保它们安全且适合地形。合规性还表明产品质量良好,并且将按承诺工作。

UL、CE、RoHS 和 IP 等级

优质拨动开关遵循安全和环境规则,以确保用户安全并使产品使用寿命更长:

UL(美国保险商实验室):UL 仪器意味着开关符合可验证的高安全标准。

CE 标志:CE 标志是对在欧洲经济区内零售的详细信息的征集,以确保它们符合健康、安全和环境安全规范。

RoHS(有害物质限制):RoHS 是一项限制使用铅和汞等危险材料的法规。

IP 条件(入口保护):显示传输如何正确地保持灰尘和水的排除,这对于交换机能够在室外或船上使用至关重要。

何时考虑军用或人工级

军用级或人造级拨动开关具有冗余特性,使其更加可靠和耐地形。其中包括更长的机械和电气寿命、排斥冲击和振动的能力,以及在危险或关键环境中运行的好处。

结论

拨动开关是一种可靠的多功能组件,用于控制各种应用中的电路。了解类型、功能和安装有助于您选择适合家庭或工业用途的产品。为确保耐用性和安全性,请始终选择适合您需求的型号。