微型开关能用多久?

微动开关是小而必不可少的组件,从家用电器到工业机器,无所不包。它们的使用寿命会影响系统可靠性、维护计划和安全性。本博客解释了微动开关通常可以使用多长时间、影响其耐用性的因素以及如何使其使用寿命更长。

什么是微动开关及其使用寿命为何重要

在深入研究其耐用性之前,首先了解微动开关的全部内容以及为什么它的可靠性是设计系统时的核心问题,这很有用。

快速浏览微动开关的实际功能

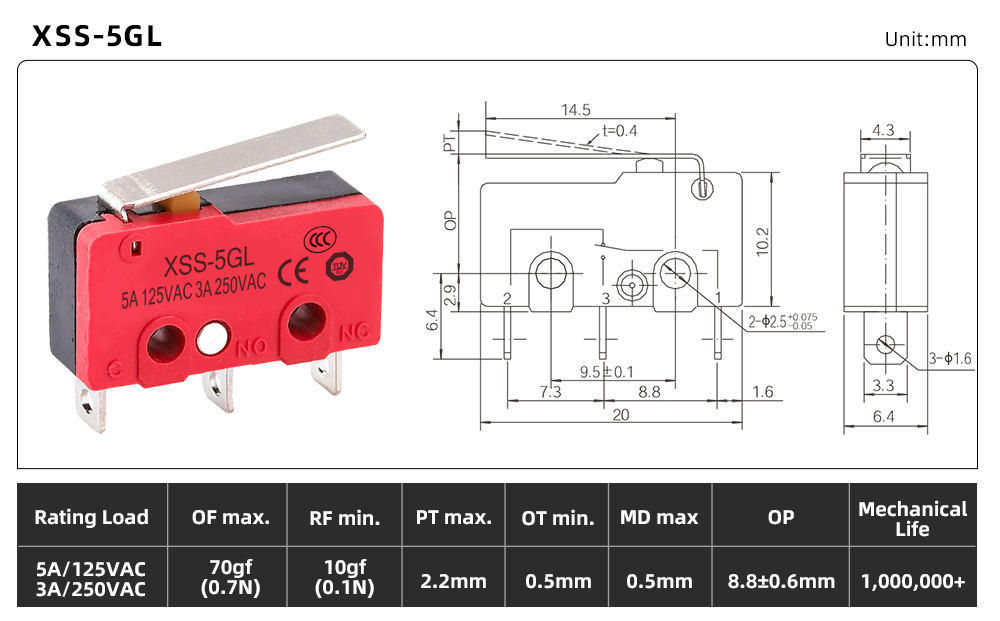

速动开关(也称为微动开关)被指定为通过非常低的物理力激活,并且通常在激活时发出快速、明确的“咔哒”反应。它通常伴随着三个端子,即公共 (COM)、常开 (NO) 和常闭 (NC)。经常使用这些开关的应用是当存在安全、自动化和重复运动的某些方面时,包括电梯按钮、微波炉门或制造机器上的限位开关。

它们精度高且结构紧凑,适用于高频驱动设置。然而,每次按下都会缩短开关的有限使用寿命。

为什么了解使用寿命对系统设计师和工程师很重要?

作为工程师,每个子系统都应该实现它注定要提供的整体系统性能。当微动开关在到期时间之前烧坏时,它不仅会带来不便。它可能会导致缺乏维护、安全隐患,甚至系统故障。微动开关的预期寿命将是确定维护期的重要因素,并且其持续功能不会中断。

微动开关在实际条件下能用多久?

微动开关通常以惊人的高寿命规格进行宣传,但性能可能因应用而异。

机械寿命和电气寿命的区别

微动开关的耐用性通常有两个不同的方面:

机械寿命:机械寿命是开关可以连接到电气负载的驱动循环次数。这可能非常大,例如许多高质量的微动开关被指定为 100 万至 1000 万次循环。

电气寿命:但是,是开关在不损坏的情况下可以运行到负载值的次数。这通常较少,为 100000 到 100 万次循环,这取决于施加的电流和电压。

基于应用类型的实际寿命范围

微动开关的长度取决于使用和应用地点。 例如:

- 电器或电脑鼠标:消费电子产品:1,000,000 至 3,000,000 次机械循环。

- 工业自动化系统:500,000 次至 500 万次循环,具体取决于占空比和环境。

- 重型机械:由于负载增加,它的电气寿命通常会缩短,在某些情况下,电气寿命可能低至 100,000 次循环。

无法在实验室测试中表示的现场作和环境条件通常以非标准方式产生这些结果。

什么影响微动开关的使用寿命?

最强大的微动开关在误用超出其设计限制时容易过早损坏。与它们的运行方式和环境相关的许多因素会影响它们的生活。

负载类型、开关速率和触点应力

微动开关的耐用性是受电气负载性质影响的一个非常重要的因素。在电感负载(如电机)之间切换会导致电弧,电弧比开关纯电阻负载(如加热元件)磨损触点的速度更大。

此外,高开关速率导致磨损更快,并且由于机械对准不当或驱动力过驱动而产生的接触应力会使部件内部变形,这两者都可能是缩短寿命的主要原因。

环境应力的作用——灰尘、湿气和振动

环境状态也至关重要。开关内部可能会因暴露于灰尘、湿气或化学蒸气而腐蚀或污染。间歇性故障可能是由于振动造成的,某些连接可能会松动。

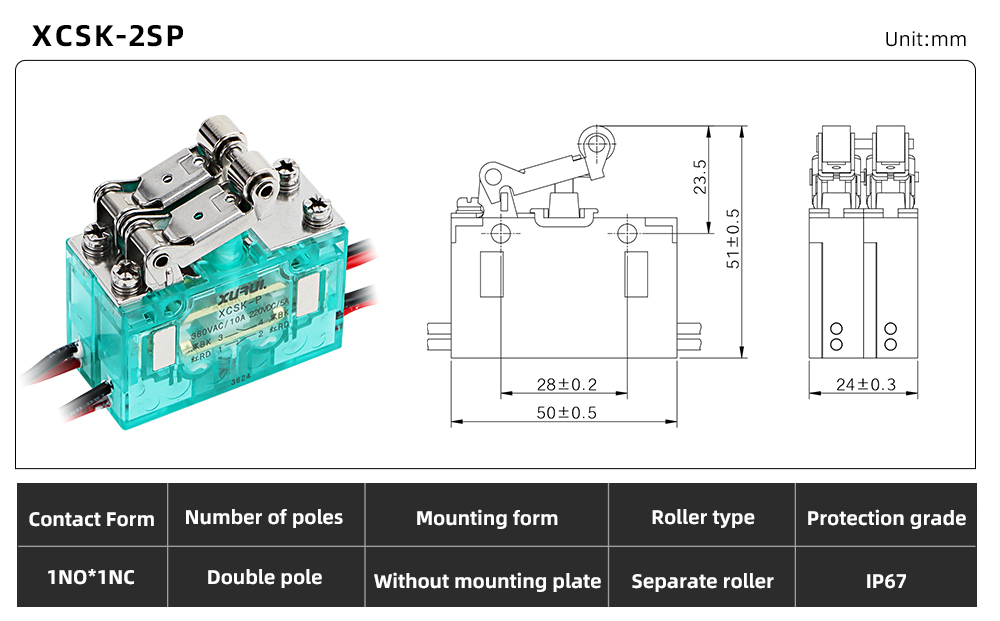

这就是为什么有时建议在恶劣环境是过程的一部分时使用密封或 IP 级微动开关(例如 Xurui 提供的微动开关)的原因。此类开关具有防潮、防振和防尘等特点,从而延长了其使用寿命。

为什么微动开关比预期更早失效?

微动开关并非坚不可摧,早期故障是实践中的典型场景,并且通常是可以避免的。

过载、电弧和电气滥用

电气过载是过早失效的最常见原因之一。当额定电流为 5A 的开关与 10A 一起使用时,电弧可能会穿过触点,触点表面会烧毁。这不仅会进一步暴露于电阻之下,还会导致触点焊接在一起,使开关永久处于一个位置。

另一个误解是使用不适合微动开关的高压或浪涌电流。即使是这种滥用也会严重缩短电气寿命。

不良的安装实践

机械磨损和应力可能导致错误的安装或对准。执行器供应商应特别注意以下事项:执行器或杠杆定位不当会导致开关无法完全接合或双重驱动,这也会导致过早退化。

避免因安装错误而过早失效的最简单方法是用正确的执行器牢固地固定微动开关,最后避免拉紧电缆。

选择满足使用寿命要求的微动开关

选择合适的微动开关不仅限于做出最实惠的选择。它需要了解您的应用程序的要求,然后相应地对应开关。

将规格与工作相匹配,而不仅仅是价格

仅通过查看微动开关的价格来做出决定意味着您可能会遇到更高的更换率、停机时间甚至破损。始终将一些重要规格(如额定电流、驱动力和 IP 额定值)与您实际的性能要求保持一致非常重要。

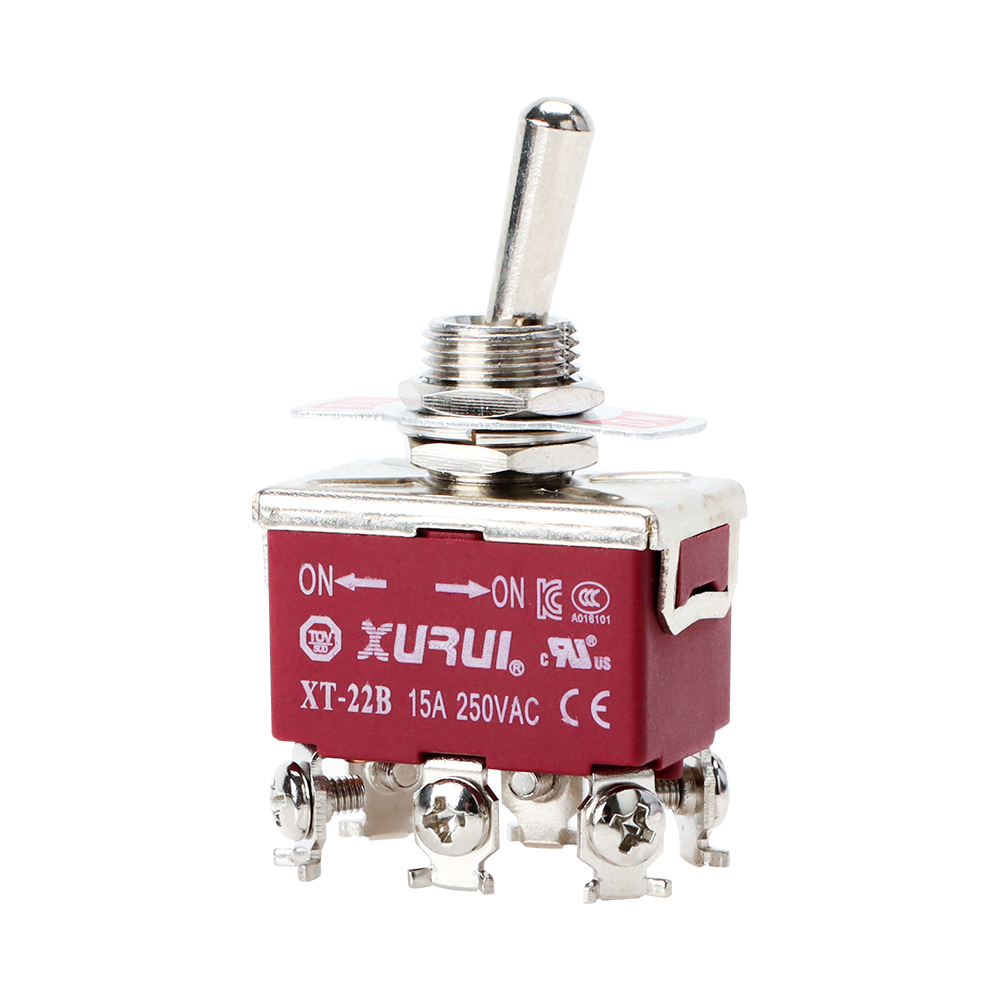

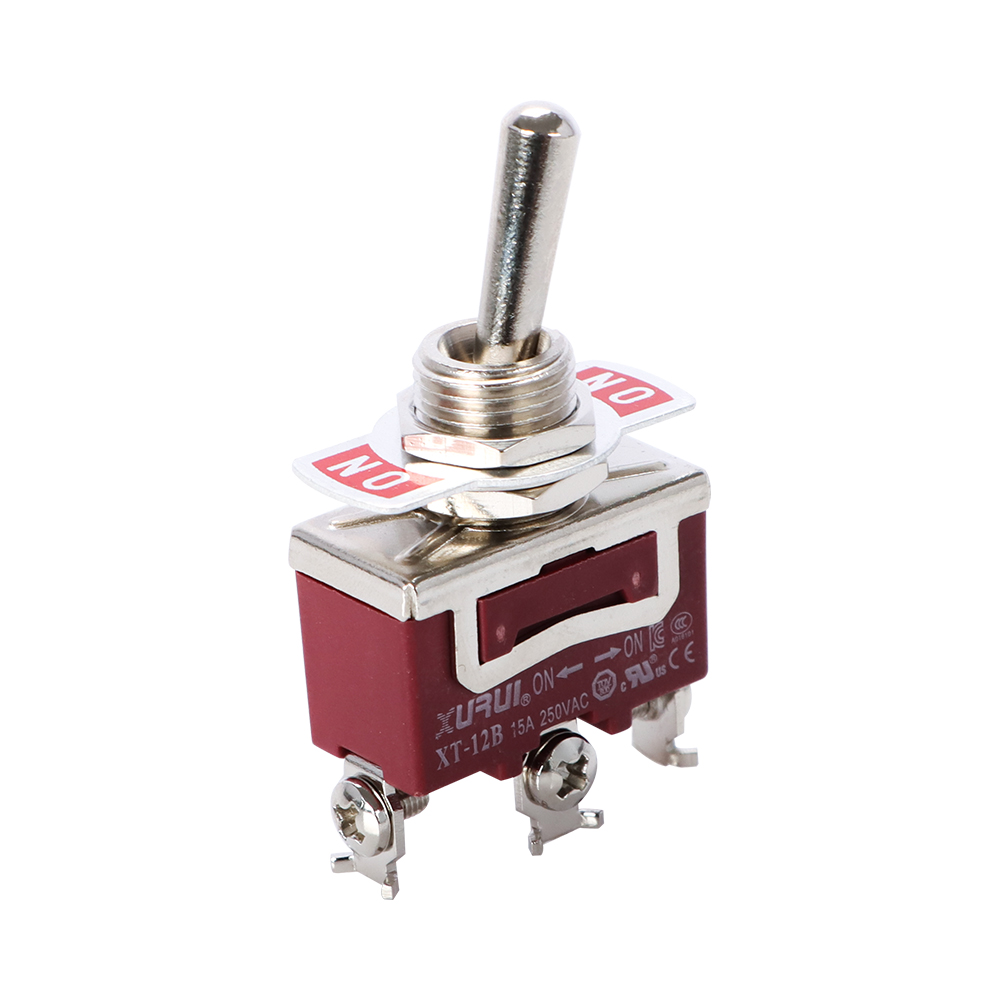

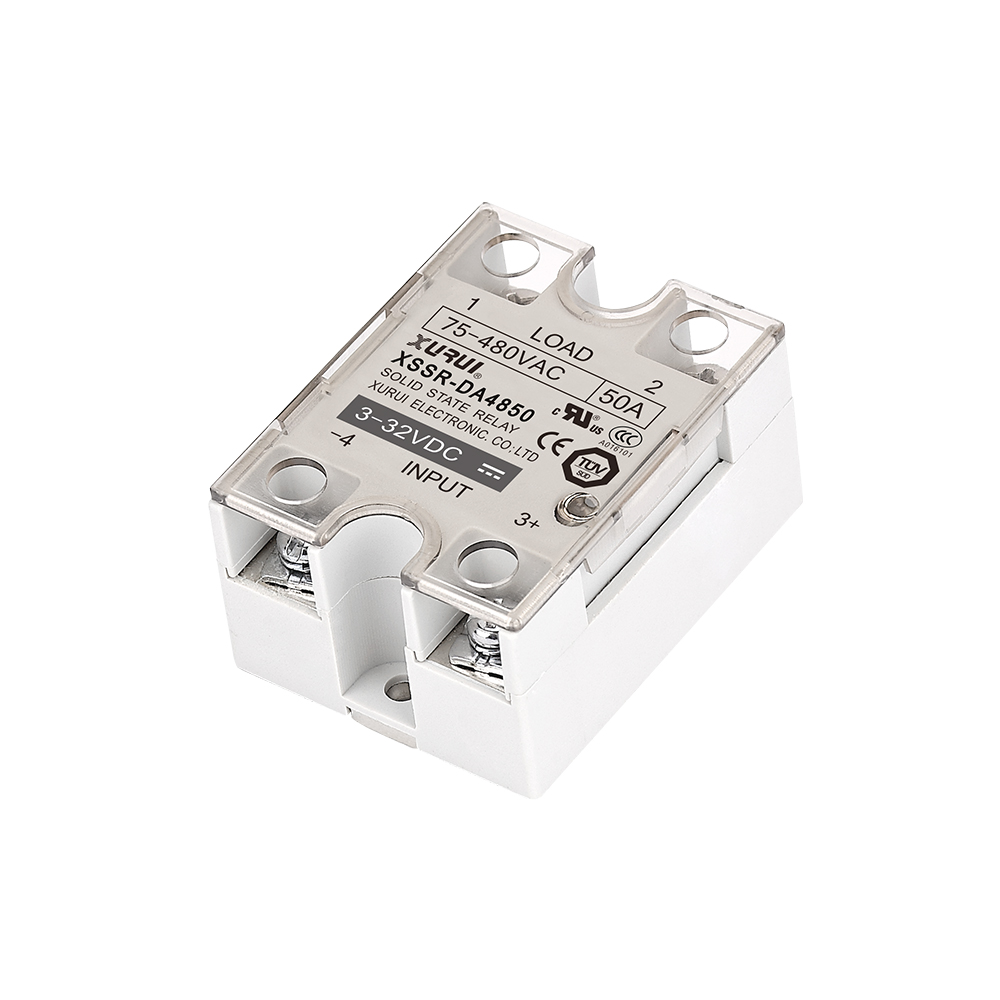

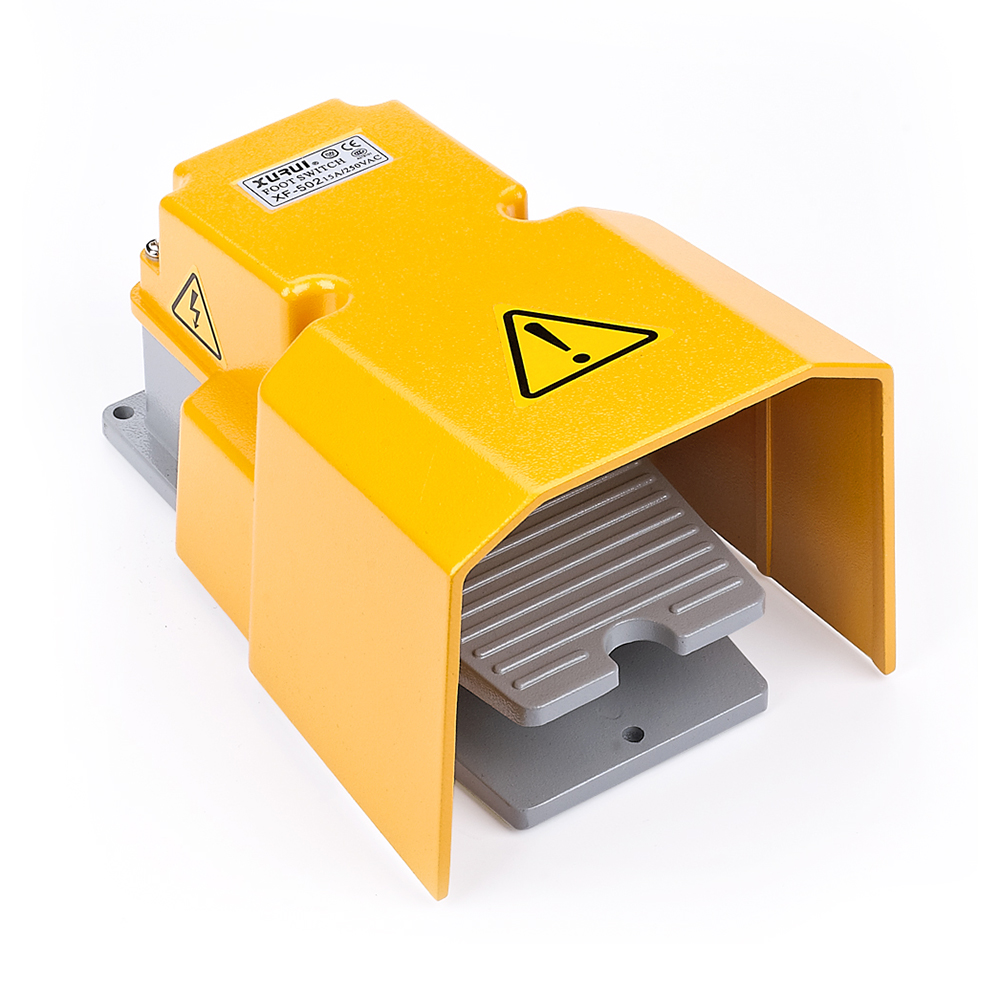

我已经探索了信誉良好的制造商的几种选择,包括 XURUI 交换机制造商。他们的一些型号专为高速应用或工业环境中的持久使用而设计。

订购前要询问供应商的哪些内容

最好开始问:

- 被测机械和电气元件的寿命是多少?

- 该开关在什么样的负载下进行了优化?

- 它是否适用于工业或安全关键型应用?

- 它是否密封了任何保护质量?

这些是重要的答案,可以为您节省犯任何错误的费用,并让产品在您的环境中以正确的方式工作。

如何让微动开关使用寿命更长

适当的预防措施将大大有助于延长微动开关的使用寿命,尤其是在恶劣条件下。

使用正确的电路附件保护触点

可以避免电弧,并且可以通过添加缓冲电路、反激二极管(在电感负载的情况下)或作继电器来关闭开关电流来保护微动开关的内部触点。

此类设备最初可能会产生少量费用,但从长远来看,它可能会花费开关的 2 或 3 倍的电力寿命。

将维护融入您的日常工作中

应定期检查。检查任何物理磨损、灰尘或变色的迹象。当您观察到退化症状时,请事先更换开关。随着时间的推移,性能和可靠性的提高是通过例行检查和适当的清洁。

结论

那么微动开关的寿命是多少呢?根据交换机的使用情况、环境和质量,所有这些都可能会有所不同(如在 100,000 个周期到超过 1000 万个周期的范围内)。但是,您可以通过仔细选择、正确安装和良好的维护技术,让您的微动开关使用数年。

根据应用选择微动开关。XURUI 交换机有多种优质产品可供选择,以满足您的需求。