文章

固态继电器的预期寿命是多少?

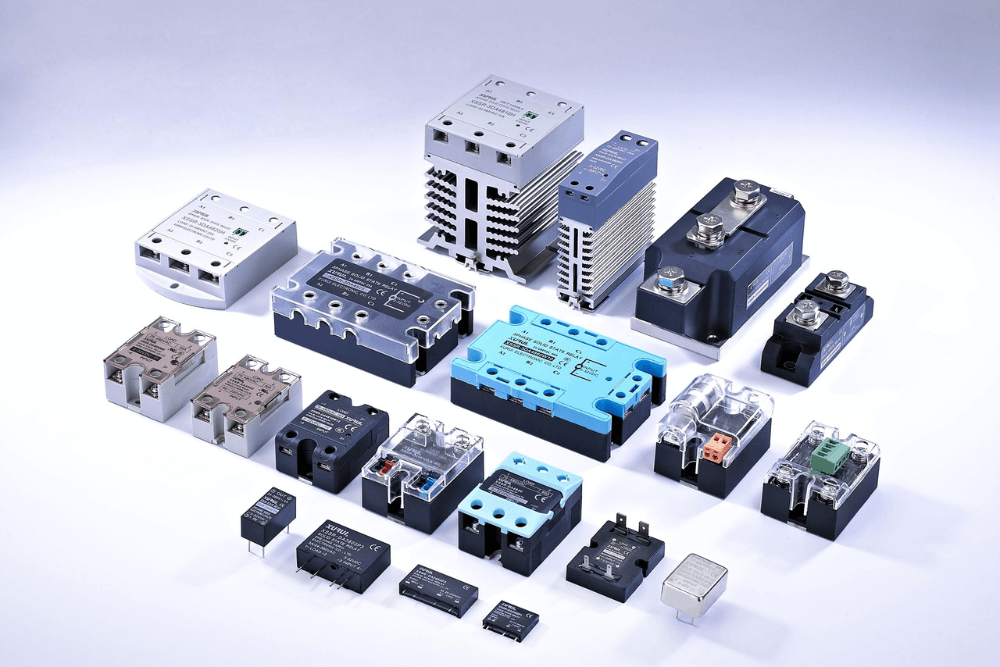

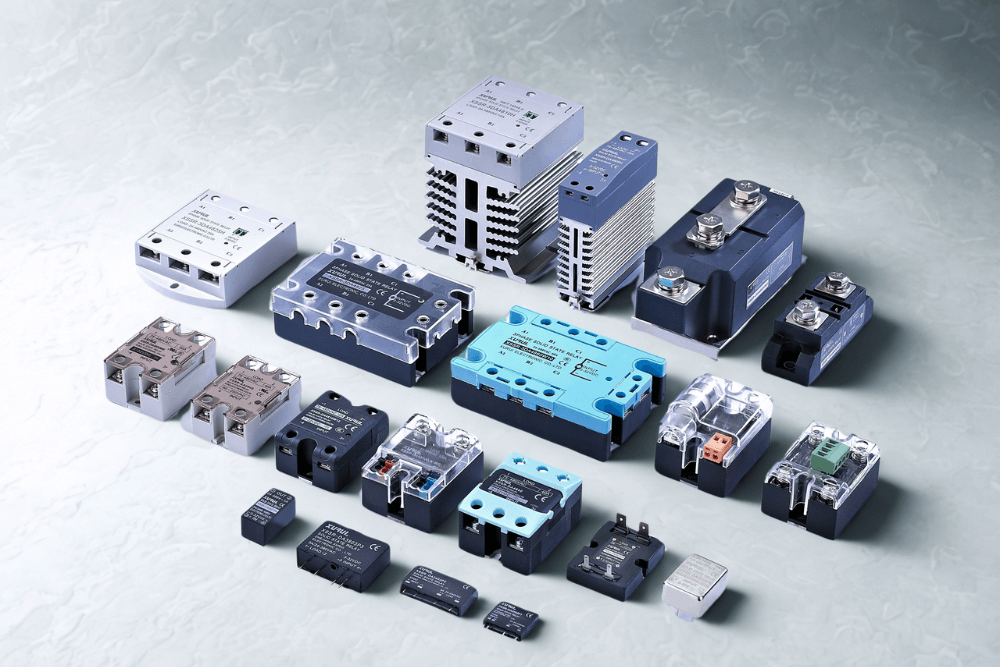

固态继电器 (SSR) 在现代电子和工业应用中至关重要,具有长寿命、可靠性和安静运行等优点。 与机电继电器 (EMR) 不同,SSR 使用半导体在没有物理接触的情况下进行开关。 本指南涵盖了 SSR 的使用寿命、影响其使用寿命的因素以及延长其性能的技巧。 从制造商处购买时,了解 SSR 使用寿命至关重要,以确保最佳设计和节省成本。

固态继电器的预期寿命是多少?

为了计划维护并确保系统的长期稳定性,您需要知道固态继电器的使用寿命。 本节讨论机械开关之间的主要区别,并提供其预期寿命的数据驱动估计。

SSR 与机械继电器有何不同

在进入数字之前,重要的是要了解为什么 SSR 的使用寿命自然比机械开关更长。 固态继电器中没有移动部件。 为了工作,它不使用机械链路,而是使用三端双向可控硅开关、晶闸管或 MOSFET,它们是半导体开关元件。 这消除了触点磨损和弹跳,这是机械开关故障的主要原因。

正因为如此,固态继电器可以切换数百万甚至数十亿次,使其比标准继电器更可靠、使用寿命更长。

基于行业数据的平均寿命

几家固态继电器制造商发布的数据表明,在完美情况下,平均 SSR 可以持续 20 到 1 亿发子弹。 当在现实世界中使用时,这可能意味着在受控环境中使用了 10 到 20 次。

为什么了解 SSR 生命周期对业务至关重要

当公司或业务系统出现故障时,成本可能会很高。 公司可以通过根据固态继电器的预期使用寿命规划预防性保护来避免系统故障和意外的救济成本。

此外,选择合适的固态继电器制造商也很重要——一家能够保证质量并彻底测试其产品的制造商。 它确保您的 SSR 符合其使用寿命的要求,并在您的特定应用中可靠地工作。

影响SSR寿命的关键因素

不同的 SSR 在不同的情况下工作,有几个因素会显着影响其持续时间。 让我们看看是什么让您的固态继电器在现实世界中工作。

负载类型:电阻式与电感式

固态继电器控制什么样的负载对其使用寿命有重大影响。 大多数时候,处理电阻负载(如吸盘或灯)的 SSR 使用寿命更长,因为电流消耗稳定可靠。

然而,电机和磨机等迷人的负载会产生电压跳跃和磁通电流,从而对 SSR 的电路造成压力并可能缩短其使用寿命。 与您可以信赖的固态继电器制造商合作可以帮助您选择用于电感用途的 SSR。

热条件和热管理

热量是杀死 SSR 的主要因素之一。 过多的热量积聚会损坏外部芯片并导致设备早熟失效。 始终使用散热器并确保固态继电器周围有足够的顺风。

为了保证寿命,许多固态继电器制造商提供内置热控制系统的类型或建议合适的热设备。

开关频率和电应力

打开和关闭东西通常会给电力带来压力并产生更多热量。 如果额定值不正确,电机驱动器或机器人化系统等高频用途可能会延长 SSR 的使用寿命。

选择设计为高频率运行且结冰(在低于其最大容量以下工作)的 SSR 可以显着延长其使用寿命。

安装环境及保护措施

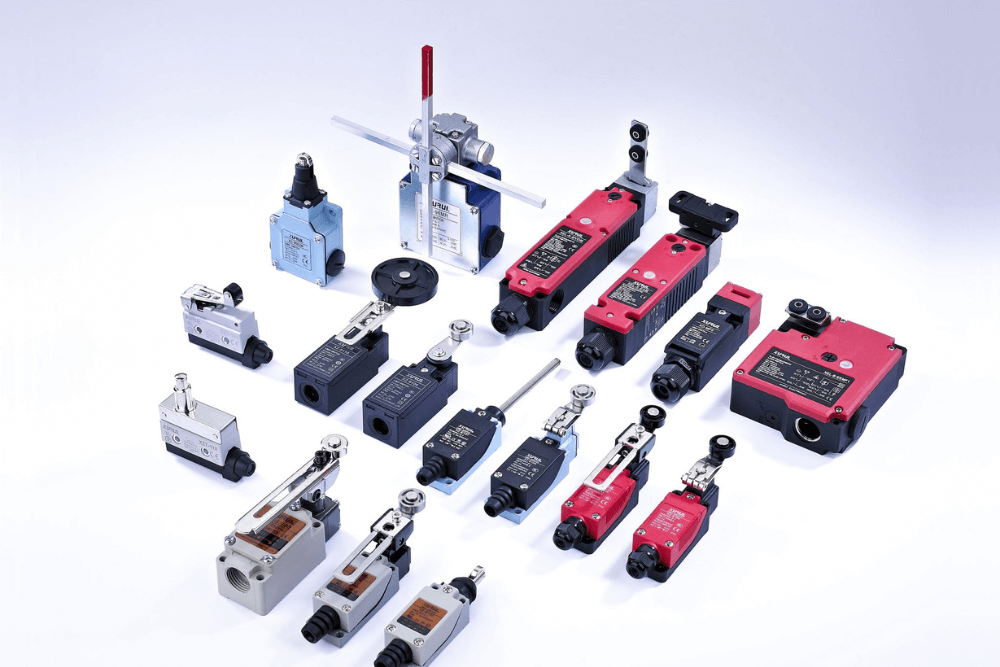

放置在肮脏、潮湿或容易晃动的环境中的 SSR 可能会更快地分解。 在这些情况下,需要密封环境并建造安全的避难所。 一些最好的固态继电器制造商制造的类型经过加固,可以在恶劣的条件下工作。

使用正确的接地、浪涌保护和绝缘也可以帮助连接持续更长时间。

构建质量和组件设计的作用

SSR 有不同种类。 使用高质量的电子产品、散热器和 PCB 材料是决定物品使用寿命的重要因素。 始终从具有良好特性和严格质量控制规范的固态继电器制造商处购买 SSR。

一开始购买劣质型号可能会更便宜,但从长远来看,如果它们过早损坏,它可能会给您带来更多。

如何延长固态继电器的使用寿命

尽管 SSR 的使用寿命很长,但您可以采取一些措施来延长它们的使用寿命。 这部分会为您提供有用的建议,以确保您的固态继电器安全工作多年。

为您的应用程序选择正确的 SSR

您使用的 SSR 规范必须适合您的目的。 假设货物的类型、功率、电流和周围环境。 不匹配可能会导致完成的工作太少或太多,从而导致事先失败。

为了帮助您选择最适合您系统的型号,您可以信赖的固态继电器制造商将为您提供数据表、技术支持和工具。

使用散热器和热界面材料

散热器对于将温度保持在适当的水平非常重要。 尽管如此,如果您的固态继电器没有足够的冷却,当它没有大量货物时,它确实会变得太热。 将 SSR 放置在散热外壳上并将其与热接触装备配对可以显着延长其使用寿命。

应用缓冲电路和过压保护

过压安全装置可防止瞬变造成的伤害,缓冲电路有助于减轻磁负载引起的电压尖峰。 添加这些简单的电路可以大大减轻固态继电器的电气应力,这在工业和电机控制设置中特别有用。

不同应用中的实际寿命

SSR 在现实世界中的效果如何很大程度上取决于它的用途。以下是固态开关如何在各种领域和设置中工作的一些示例。

工业机械和工厂自动化

在工厂中,SSR 通常与众多开关和大量电力一起运行。如果您从优秀的固态继电器制造商处购买它们并确保它们正确放置冷却,它们应该可以使用 10 到 15 年。

在这些情况下,缓冲器可以保护 SSR,并且应在定期维修期间进行检查。

HVAC 系统和温度控制器

许多暖通空调系统使用固态开关以安静、准确的方式控制温度。在理想条件下,SSR 可以使用 15 年以上,因为这些系统运行频率较低,并且通常控制电阻负载。

电机控制和高浪涌电路

由于磁通电流和电压变化,电机设置很难进行。使用包含安全功能(例如过零识别或软发射)的 SSR 可以使其更可靠、使用寿命更长。

同样,从可估量的固态继电器制造商那里获得 SSR 可以确保它能够处理此类负载。

固态继电器何时以及为何过早失效

事实上,尽管SSR以其长期持续的商品而闻名,但如果被误用或在错误的情况下,它们可能会早熟失效。担心这些影响,以解决意想不到的问题。

常见安装错误和误用

如果 SSR 放置不正确,没有让足够的热量逸出,或者使用它们高于推荐的电压或电流,它们可能会过早失效。为避免出现此类错误,请始终遵循固态继电器随附的安装说明。

停靠寿命的环境因素

随着时间的推移,灰尘、湿气、酸性盛宴和机械应力会损坏 SSR 走廊。使用设计为可承受恶劣条件的容器和型号。

如果您不确定,请咨询固态继电器的制造商,以找到适合您情况的类型。

表明即将失败的迹象

尽管 SSR 经常在没有通知的情况下失败,但以下是一些迹象表明它们可能会失败:

·过多的热量或建筑物的颜色发生变化

·打开和关闭或行为不一致

·嗡嗡声(对于 SSR 来说并不典型)

·透明烧伤或裂纹

如果发现任何这些迹象,应立即更换该物品

结论

与机械继电器相比,固态继电器 (SSR) 具有卓越的使用寿命、可靠性和安静的运行。它们的使用寿命可以从 10 年到 20 年不等,具体取决于负载类型、热条件、开关频率和环境因素等因素。为了最大限度地延长其使用寿命,必须为您的应用选择正确的 SSR,确保正确安装,并有效管理热和电应力。通过遵循这些准则并从信誉良好的制造商处购买,您可以延长 SSR 的使用寿命并避免代价高昂的故障。定期维护和注意磨损迹象可以进一步帮助确保您的 SSR 在未来几年内可靠运行。